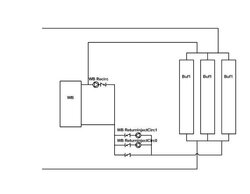

I was thinking of something like this for next year to keep the mixing temp just above 140*

http://www.pexsupply.com/Tekmar-712-1-1-4-Brass-3-Way-Mixing-Valve-4866000-p

http://www.pexsupply.com/Tekmar-153-Mixing-Setpoint-Control-Floating-Action-4798000-p

http://www.pexsupply.com/Tekmar-741-Actuating-Motor-for-34-Way-Mixing-Valves-5908000-p

Its a little $$$$$$ but its only money !

!

Rob

http://www.pexsupply.com/Tekmar-712-1-1-4-Brass-3-Way-Mixing-Valve-4866000-p

http://www.pexsupply.com/Tekmar-153-Mixing-Setpoint-Control-Floating-Action-4798000-p

http://www.pexsupply.com/Tekmar-741-Actuating-Motor-for-34-Way-Mixing-Valves-5908000-p

Its a little $$$$$$ but its only money

!

!Rob