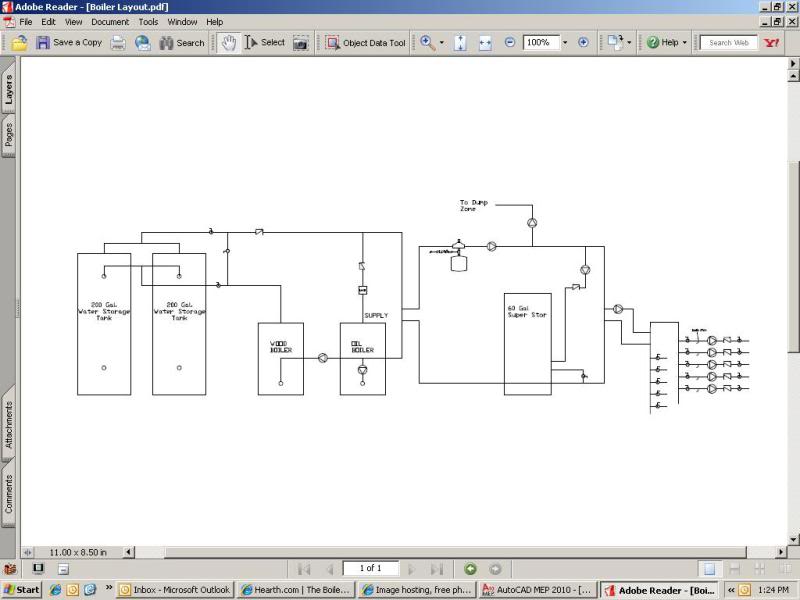

Here is a drawing as it sits right now. I am trying to redo my piping to try and make this thing work better. This is conventional New Yorker Boiler. I know I need to change the boiler but that isn't going to be for a few years so I need to make it somewhat functional. I already have a tekmar 156 that I would like to use for charging of the tanks. I also would like to get a termavor to protect the boiler (where on the drawing should I put this). I am looking for any and all ideas. Thanks, Brian

Need help on Piping Redo

- Thread starter Blevesque

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.