If dialog below is to unclear I think I can figure it out using 45 degree distance if I knew the following:

1. What is the distance to subtract from the 45 degree distance for the two 45 elbows on each end?

Is 3.54" per 45 degree elbow correct?

2. What does using a 90 elbow add to the length? Is 7.3" on each end correct?

3. Is 1 1/2 subtracted from each pipe and elbow for joint overlap?

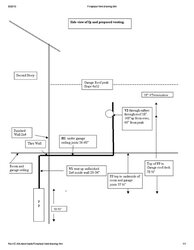

Venting for Kozy Heat Slayton using 5x8 double wall Selkirk venting. I need verification this routing will

work.(see attachment) It appears to meet the requirements in the Slayton install manual. I could

eliminate the second 90 elbow after the FP and replace it with two 45's if I could figure out the math.

I plan on using Selkirk as it fits with out an appliance adapter. I would like to use standard pipe if

possible, there is a 4-10" adjustable vent if necessary. 1" clearance from combustibles. Here are the

numbers necessary to do the math. horizontal from FP Vent connection O.C. through wall =18 3/4".

Horizontal from garage wall to center of 24" O.C. garage rafter is 43". Total horizontal run would

be from FP vent connection O.C. 18 3/4" +43"=61 3/4". Vertical from FP vent connection to bottom of

top sill on interior wall is 42 1/2". Add 3" for a double sill to 45 1/2" from FP to bottom of Garage rafter.

The garage rafters are 24" o.c. and run parallel to the FP.

1. What is the distance to subtract from the 45 degree distance for the two 45 elbows on each end?

Is 3.54" per 45 degree elbow correct?

2. What does using a 90 elbow add to the length? Is 7.3" on each end correct?

3. Is 1 1/2 subtracted from each pipe and elbow for joint overlap?

Venting for Kozy Heat Slayton using 5x8 double wall Selkirk venting. I need verification this routing will

work.(see attachment) It appears to meet the requirements in the Slayton install manual. I could

eliminate the second 90 elbow after the FP and replace it with two 45's if I could figure out the math.

I plan on using Selkirk as it fits with out an appliance adapter. I would like to use standard pipe if

possible, there is a 4-10" adjustable vent if necessary. 1" clearance from combustibles. Here are the

numbers necessary to do the math. horizontal from FP Vent connection O.C. through wall =18 3/4".

Horizontal from garage wall to center of 24" O.C. garage rafter is 43". Total horizontal run would

be from FP vent connection O.C. 18 3/4" +43"=61 3/4". Vertical from FP vent connection to bottom of

top sill on interior wall is 42 1/2". Add 3" for a double sill to 45 1/2" from FP to bottom of Garage rafter.

The garage rafters are 24" o.c. and run parallel to the FP.