As many of you know if you've been watching the threads, in addition to getting things ready for the Hearth Party, I've been working on an extensive article on Hearth Design and construction for the Wiki. I would appreciate general review and comments, but I need one specific part checked over specifically, preferably by folks with access to good "official" documentation.

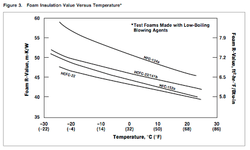

One of the things that I've been running into as a problem is coming up with a table of R-values for different possible materials that one might want to put into a hearth pad. I started by cribbing the table that Tom Oyen had over in his Sweep's library, and then adding such things to it as I find in other sources. However I'm finding discrepancies in some of the values, and I want to see if there are folks like Elk or Corie that can verify the correct values, and possibly give better sources for them - Additional items are also welcome. Note that currently it's a bit tricky to edit the table, I had to take a screen shot of it and paste the image into the article in order to make the columns work properly, so it would be best if you could post anything extra in this thread and I can then make the changes on my end.

The items I'm having particlular problems with are:

Ceramic Tile 1/4" 0.020 Tom says R=0.02, Hearthstone says 0.01

Concrete 1" 0.950 Tom says R=0.95/inch, but masonry cement is 0.1 per 1/2", and I don't see that much difference between the two to account for the huge R difference.

Concrete Block empty core 8" 1.000 This value came from a Hearth article, and seems awfully low just from the thickness of the blocks, not to mention the materials in them

Gypsum or Plaster Board 1/2" 0.450 Seems awfully high in light of the values for other cement type boards (also is this the same stuff as sheet rock, and if so, what about the paper backing?)

Horizontal Dead Air Space 1" 0.970 3 1 This value comes from Elk, Hearthstone and ASHRAE says 0.92 per 1/8" if each layer is separated by non-combustibles, however we are already beating this one up pretty well elsewhere, I don't think we need to go into it here...

Rockwool or Fiberglass Bats 1" 3.330 I'm assuming this is the same as "mineral wool" in which case Hearthstone is only giving a value of 3.12/inch

These are the Hearthstone chart values where I found discrepancies with the other numbers...

Ceramic Tile 1/4" 0.01

Mineral Wool Insulation 1" 3.12

Horizontal Still Air 1/8" 0.92

I'm also having trouble getting the chart to reproduce accurately in the post, so I'm attaching a screenshot of it so you can see the whole thing.

Gooserider

One of the things that I've been running into as a problem is coming up with a table of R-values for different possible materials that one might want to put into a hearth pad. I started by cribbing the table that Tom Oyen had over in his Sweep's library, and then adding such things to it as I find in other sources. However I'm finding discrepancies in some of the values, and I want to see if there are folks like Elk or Corie that can verify the correct values, and possibly give better sources for them - Additional items are also welcome. Note that currently it's a bit tricky to edit the table, I had to take a screen shot of it and paste the image into the article in order to make the columns work properly, so it would be best if you could post anything extra in this thread and I can then make the changes on my end.

The items I'm having particlular problems with are:

Ceramic Tile 1/4" 0.020 Tom says R=0.02, Hearthstone says 0.01

Concrete 1" 0.950 Tom says R=0.95/inch, but masonry cement is 0.1 per 1/2", and I don't see that much difference between the two to account for the huge R difference.

Concrete Block empty core 8" 1.000 This value came from a Hearth article, and seems awfully low just from the thickness of the blocks, not to mention the materials in them

Gypsum or Plaster Board 1/2" 0.450 Seems awfully high in light of the values for other cement type boards (also is this the same stuff as sheet rock, and if so, what about the paper backing?)

Horizontal Dead Air Space 1" 0.970 3 1 This value comes from Elk, Hearthstone and ASHRAE says 0.92 per 1/8" if each layer is separated by non-combustibles, however we are already beating this one up pretty well elsewhere, I don't think we need to go into it here...

Rockwool or Fiberglass Bats 1" 3.330 I'm assuming this is the same as "mineral wool" in which case Hearthstone is only giving a value of 3.12/inch

These are the Hearthstone chart values where I found discrepancies with the other numbers...

Ceramic Tile 1/4" 0.01

Mineral Wool Insulation 1" 3.12

Horizontal Still Air 1/8" 0.92

I'm also having trouble getting the chart to reproduce accurately in the post, so I'm attaching a screenshot of it so you can see the whole thing.

Gooserider