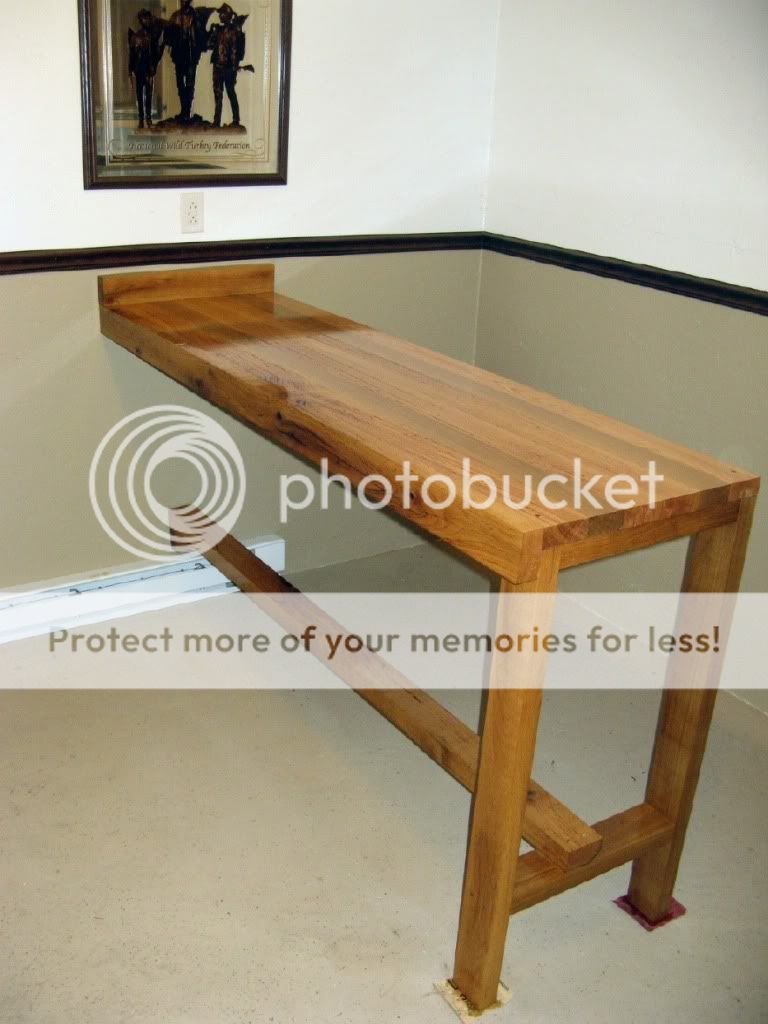

I'm in the process of building a shop (lounge/bar/etc) in my garage and am almost finished. Everything is painted, cabinets are up, fridge is in, heat is on, just working on the most important part now, the bar top, I mean workbench

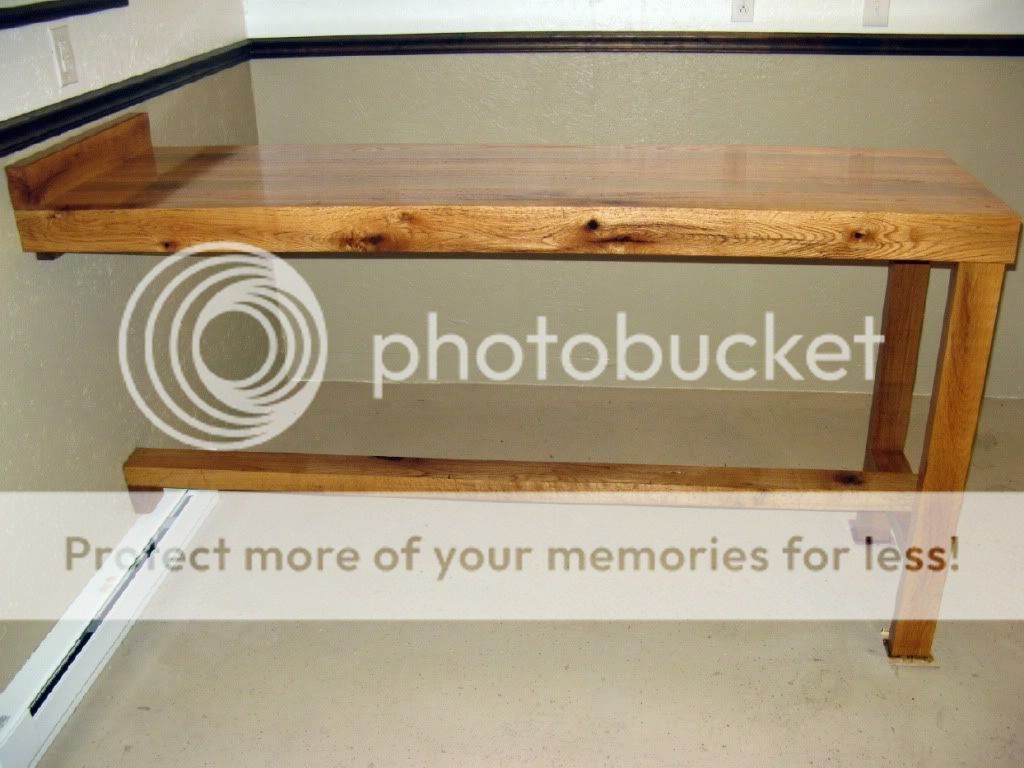

Anyway, years ago I was given a bunch of rough cut oak 2x4's. I planed them down and have put them together for a 2 foot by 6 1/2 foot bar. I'm debating on how to finish it. If any "work" is ever done here I'll have a piece of plywood to set down over the top to protect it.

Should I just go w/ plain old oil based poly? Use a water based poly w/ a universal sealer first (for color)? A floor formulation of water or oil poly? Something simple like tongue oil or mineral oil?

What do you guys recommend for a bar?

pen

Anyway, years ago I was given a bunch of rough cut oak 2x4's. I planed them down and have put them together for a 2 foot by 6 1/2 foot bar. I'm debating on how to finish it. If any "work" is ever done here I'll have a piece of plywood to set down over the top to protect it.

Should I just go w/ plain old oil based poly? Use a water based poly w/ a universal sealer first (for color)? A floor formulation of water or oil poly? Something simple like tongue oil or mineral oil?

What do you guys recommend for a bar?

pen

! i knew that there was good money in being a moderator

! i knew that there was good money in being a moderator But, regardless, I don't want water rings.

But, regardless, I don't want water rings.