Lots of great stuff on this website! Just received my eko 40 , I will be heating my house and detached garage with the eko. The eko is located in the garage which has living quarters above it. I have installed radiant o2 barrier Pex in the garage floor. It's 3 circuits about 275' each. I ran the circuits to a manifold in my mechanical room about 5' from the eko. I also have the insulated Pex running underground to my house which is 75' away, I will be tying it into a well MacLaine oil boiler, my house has hot water baseboard, it's a 2 story cape cod 2300 square feet of living space not including basement. The garage upstairs I will be heating is about 800' square feet. The mechanica room I built off the garage is about 32'x10 ' fully insulated which holds 25 face cord of wood and the eko and a 400 gallon propane tank that I wellded 3- 1 1/4 " taps on the top and 3- 1 1/4" on the bottom...( wasn't sure how many I needed) this is where the progress has slowed to a crawl, as a finished carpenter I am totally out of my element, when it comes to designing the piping system. I know I need to protect boiler from shock, I need two water temperatures for In floor and base board,dump zone...and the list goes on but not sure how to put it on paper ?? And get my materials order...any help would be much appreciated!!

New Eko 40

- Thread starter Millwork

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

easternbob

Member

congrats on the boiler.

I to am out of my element when it came to all the piping stuff. What I did was hire a hvac guy as a consultant on an as needed basis. Had him over to the house and he told me what to do and what to install, I did the work. I'm guessing you must know a few heating guys, maybe you can trade.

I to am out of my element when it came to all the piping stuff. What I did was hire a hvac guy as a consultant on an as needed basis. Had him over to the house and he told me what to do and what to install, I did the work. I'm guessing you must know a few heating guys, maybe you can trade.

BoiledOver

Minister of Fire

Ya might want to consider insurance too, without licensed installer can be troublesome. Hope ya get all squared away with your new heating system.

jeffesonm

Minister of Fire

You can find some basic piping info here: https://www.hearth.com/talk/threads/simplest-pressurized-storage-system-design.16567/

huffdawg

Minister of Fire

Seems like our applications are quite similar. Check out this link it shows pretty much what I have done . http://96.54.66.117/public/huff.html

My house is 2 storey 2800sf and I have a 900sf shop with a 900sf suite above. The 2 storage tanks are 500 gals each and the hydraulic separator tank is 150 gals. all boiler and tank piping is a mix of 1-1/4" copper or black iron and the house loop piping is 1-1/4 oxypex. 50' to and 50' back.

I have one 15/58 pump for the upstairs baseboard loop in my house

1 15/58 for the infloor heating on the bottom floor.

15/58 for the dhw tank in house and 1 for the dhw tank in shop.

15/58 for the shop floor

15/58 for storage

15/58 for house loop

taco 007 for near boiler pump.. came with my EKO 40 when purchased.

On the drawing there is a few items not shown.. A honeywell air scrubber or ejector, which is located a couple feet from the boiler discharge.

- coin vents on top of each tank and on the high spots in the piping

-Two extrol 120 expansion tanks which are plumbed to the top of the hydraulic separator

- several isolation valves.

This is just to give you an idea. there are many different ways to plumb boiler systems .

http://www.ebay.com/sch/i.html?_from=R40&_sacat=See-All-Categories&_nkw=GRUNDFOS UPS15-58 FC 3 SPEED CIRCULATOR PUMP&_mPrRngCbx=1

I would try to get more storage capacity looks like you have lots of space for it.

What size is the insulated pex to your house?

Will you be heating your domestic hot water?

Huff

My house is 2 storey 2800sf and I have a 900sf shop with a 900sf suite above. The 2 storage tanks are 500 gals each and the hydraulic separator tank is 150 gals. all boiler and tank piping is a mix of 1-1/4" copper or black iron and the house loop piping is 1-1/4 oxypex. 50' to and 50' back.

I have one 15/58 pump for the upstairs baseboard loop in my house

1 15/58 for the infloor heating on the bottom floor.

15/58 for the dhw tank in house and 1 for the dhw tank in shop.

15/58 for the shop floor

15/58 for storage

15/58 for house loop

taco 007 for near boiler pump.. came with my EKO 40 when purchased.

On the drawing there is a few items not shown.. A honeywell air scrubber or ejector, which is located a couple feet from the boiler discharge.

- coin vents on top of each tank and on the high spots in the piping

-Two extrol 120 expansion tanks which are plumbed to the top of the hydraulic separator

- several isolation valves.

This is just to give you an idea. there are many different ways to plumb boiler systems .

http://www.ebay.com/sch/i.html?_from=R40&_sacat=See-All-Categories&_nkw=GRUNDFOS UPS15-58 FC 3 SPEED CIRCULATOR PUMP&_mPrRngCbx=1

I would try to get more storage capacity looks like you have lots of space for it.

What size is the insulated pex to your house?

Will you be heating your domestic hot water?

Huff

Last edited:

Thanks for the replies everyone!

Huff , I am planning on heating my domestic hot water with the wood boiler currently I am using a Amtrol tank off my oil boiler the insulated pex is 1" What is a hydronic seperator? ( sorry for the ignorance ) Is one extrol 120 tank enough for 400 gallons of storage?

Huff , I am planning on heating my domestic hot water with the wood boiler currently I am using a Amtrol tank off my oil boiler the insulated pex is 1" What is a hydronic seperator? ( sorry for the ignorance ) Is one extrol 120 tank enough for 400 gallons of storage?

huffdawg

Minister of Fire

Thanks for the replies everyone!

Huff , I am planning on heating my domestic hot water with the wood boiler currently I am using a Amtrol tank off my oil boiler the insulated pex is 1" What is a hydronic seperator? ( sorry for the ignorance ) Is one extrol 120 tank enough for 400 gallons of storage?

Sorry.. I meant hydraulic. http://www.lochinvar.com/_linefiles/BVU-01.pdf .. I have two extrol 110's for 1175 gals of water.

ewdudley

Minister of Fire

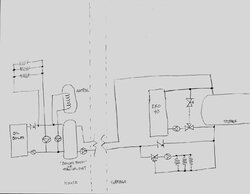

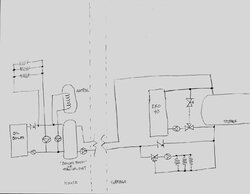

Here's a good way of doing it. The "Boiler Buddy" is an example of a hydraulic separator/buffer. Lots of other brands available for many hundreds of dollars, or you can fabricate one yourself locally for dozens of dollars with most any mild steel pressurizable tank of 30 gallons or so. For best control need a temperature well a foot or so up from the bottom ports and maybe another well near the top.

(The supply connections for the baseboard and DHW loops are shown at arbitrary positions along the supply header. Ideally these connections would be close to the buffer so there would little if any possibility of drawing parallel flow through the oil boiler.

Another variation would be to have the DHW circuit draw from the top of the buffer and return to a point near or above the middle, and the baseboard circuits would then draw from the middle and return to the bottom. This gives DHW priority.)

I didn't see where you said what type of heat you're using for the above-garage space so it is not drawn. If it is baseboard, radiators, or radiant panels then there is the possibility of using it for your dump zone.

Note the check valve, mixing valve, and pump arrangement for drawing water from the bottom of the hydraulic separator into your in-floor PEX. This is important for lowering your system return temperature, which enhances stratification and therefore storage capacity.

[Edit: Amtrol is an indirect DHW tank.]

(The supply connections for the baseboard and DHW loops are shown at arbitrary positions along the supply header. Ideally these connections would be close to the buffer so there would little if any possibility of drawing parallel flow through the oil boiler.

Another variation would be to have the DHW circuit draw from the top of the buffer and return to a point near or above the middle, and the baseboard circuits would then draw from the middle and return to the bottom. This gives DHW priority.)

I didn't see where you said what type of heat you're using for the above-garage space so it is not drawn. If it is baseboard, radiators, or radiant panels then there is the possibility of using it for your dump zone.

Note the check valve, mixing valve, and pump arrangement for drawing water from the bottom of the hydraulic separator into your in-floor PEX. This is important for lowering your system return temperature, which enhances stratification and therefore storage capacity.

[Edit: Amtrol is an indirect DHW tank.]

Last edited:

huffdawg

Minister of Fire

Eliott I'm not understanding the loop through the exp. tank? Or is that supposed to be a dhw tank?

ewdudley

Minister of Fire

OP says he's got an Amtrol DHW tank, like a BoilerMate maybe I'm assuming. Sorry for the confusion since so many expansion tanks are also Amtrols.Eliott I'm not understanding the loop through the exp. tank? Or is that supposed to be a dhw tank?

huffdawg

Minister of Fire

I was reading to fast and overlooked that sentence. woopsOP says he's got an Amtrol DHW tank, like a BoilerMate maybe I'm assuming. Sorry for the confusion since so many expansion tanks are also Amtrols.

Thanks for all the help! Will post a few pics in a week or soHere's a good way of doing it. The "Boiler Buddy" is an example of a hydraulic separator/buffer. Lots of other brands available for many hundreds of dollars, or you can fabricate one yourself locally for dozens of dollars with most any mild steel pressurizable tank of 30 gallons or so. For best control need a temperature well a foot or so up from the bottom ports and maybe another well near the top.

(The supply connections for the baseboard and DHW loops are shown at arbitrary positions along the supply header. Ideally these connections would be close to the buffer so there would little if any possibility of drawing parallel flow through the oil boiler.

Another variation would be to have the DHW circuit draw from the top of the buffer and return to a point near or above the middle, and the baseboard circuits would then draw from the middle and return to the bottom. This gives DHW priority.)

I didn't see where you said what type of heat you're using for the above-garage space so it is not drawn. If it is baseboard, radiators, or radiant panels then there is the possibility of using it for your dump zone.

Note the check valve, mixing valve, and pump arrangement for drawing water from the bottom of the hydraulic separator into your in-floor PEX. This is important for lowering your system return temperature, which enhances stratification and therefore storage capacity.

[Edit: Amtrol is an indirect DHW tank.]

View attachment 144595

ps are those taco bumble bee pumps worth the extra money for the 85 percent efficiency ?

Attachments

Well I am up and running! What's a good temp to set controler at, I set it for 180f seems to mostly stay at 177 and not move much so fan is constantly running, I am heating 500 gallons of water, I think I need to insulate the storage tank better. I have base board in house and once it runs threw oil boiler gauge is reading 160. I would like that gage to be 180 or so. I think I am loosing heat at the storage tank?

When I installed my new boiler, I ordered most of my valves, fittings, etc from the Supply House. Much cheaper than the local supply house where you pay top price if you are not a plumber. Bought most of the copper pipe from Lowes since they don't ship 10' pieces. Supply House was much cheaper than Lowes and Home Depot doesn't carry many 1-1/4" fittings anymore.

BoiledOver

Minister of Fire

Congrats on your achievement. Load this one right up to 190-193 at the top of 1,000 gallons. The RK controller is set to 192 for the fan and then I use a separate aquastat to control the circulator. The bottom doesn't quite make it that high but around 6 degrees less maybe. Like to load the box just a little less than what it would take to get it all up to 193. If too much fuel, it sits and smolders more than my preference. Enjoy your blue flame.

BoiledOver

Minister of Fire

Inside the already insulated R-13 walls and R-30 ceiling, I used polyisocyanurate panels. Waited for them to go on sale at Menards, don't remember the price but it was a considerable discount. Put 2" on the outside wall and then framed with 1x4 boards, an enclosure that totals 4-1/2" of polyiso insulation with osb as an outer skin. Added tall feet to the propane tanks and placed 4" of rigid rockwool underneath. The rockwool was from another heating project from an earlier time.

Although this sounds like a lot, there is still standby loss. Fortunately it provides a comfortable temp all winter in the shop so the standby loss is actually not lost at all.

Right off the top of an old brain, I would say it takes about 4' x 10' of floor space, 2 Tanks stacked horizontal.

Although this sounds like a lot, there is still standby loss. Fortunately it provides a comfortable temp all winter in the shop so the standby loss is actually not lost at all.

Right off the top of an old brain, I would say it takes about 4' x 10' of floor space, 2 Tanks stacked horizontal.

stee6043

Minister of Fire

Your 40 must have it's work cut out for it with that heat load. How often do you find yourself loading it right now?

I used plain ole fiberglass batting for my tanks. I think I wrapped 2X with R30 and 3X on top. Not as fantastic as some of the higher cost options but still decent.

I used plain ole fiberglass batting for my tanks. I think I wrapped 2X with R30 and 3X on top. Not as fantastic as some of the higher cost options but still decent.

I have storage tank all insulated, three nights at 25 deg and I load it ever 12 hours and still a couple pieces of wood left... Very happy with it, today was very mild almost 50 and I accumulated a lot of tar/creasolte in upper wood chamber so when it finally burned down I opened up the flapper and threw some kindling in to burn up the crap... Not sure if that's a good idea or not but it cleaned up the wood chamber. My chimmney is 1/4 steel pipe so chimney fire can't really hurt it and it's out side of building...Your 40 must have it's work cut out for it with that heat load. How often do you find yourself loading it right now?

I used plain ole fiberglass batting for my tanks. I think I wrapped 2X with R30 and 3X on top. Not as fantastic as some of the higher cost options but still decent.

woodsmaster

Minister of Fire

I have storage tank all insulated, three nights at 25 deg and I load it ever 12 hours and still a couple pieces of wood left... Very happy with it, today was very mild almost 50 and I accumulated a lot of tar/creasolte in upper wood chamber so when it finally burned down I opened up the flapper and threw some kindling in to burn up the crap... Not sure if that's a good idea or not but it cleaned up the wood chamber. My chimmney is 1/4 steel pipe so chimney fire can't really hurt it and it's out side of building...

Creosote in the upper chamber is normal and doesn't hurt anything. It will flake off a little at atime and burn up, more forms etc.

woodsmaster

Minister of Fire

Congrats on your achievement. Load this one right up to 190-193 at the top of 1,000 gallons. The RK controller is set to 192 for the fan and then I use a separate aquastat to control the circulator. The bottom doesn't quite make it that high but around 6 degrees less maybe. Like to load the box just a little less than what it would take to get it all up to 193. If too much fuel, it sits and smolders more than my preference. Enjoy your blue flame.

Ive found my boiler to be a lot more efficient if I don't try heating the storage to max temp. I just burn a load of wood and if storage makes it around 180 that's plenty hot and last a good amount of time. Go threw a lot less wood then when I was always going for max temp

Fred61

Minister of Fire

12 hour burn with fuel left over indicates to me that there has been extensive idling and could be gumming up the firetubes and stack. Is your storage at maximum temperature at the 12 hour burn point? If so, you should cut back on your fuel load.

- Status

- Not open for further replies.

Similar threads

- Replies

- 24

- Views

- 1K

- Replies

- 20

- Views

- 824

- Replies

- 19

- Views

- 717

- Replies

- 21

- Views

- 2K