We are about to embark on the last part of our fireplace restoration/woodstove installation project: The Hearth

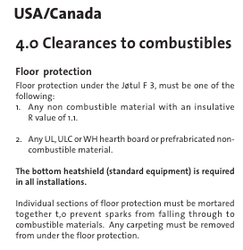

Right now, we are planning on using bluestone, but I wonder if 2" of bluestone is enough insulation under our Jotul F3. Is there an insulation board that can/should under the bluestone? Right now, we are planning on having the bluestone sit on 3/4 ply topped with mesh and wet set. All this sits over the main beam, a 6x8 old growth who-knows-what.

Thanks, Folks.

z

Right now, we are planning on using bluestone, but I wonder if 2" of bluestone is enough insulation under our Jotul F3. Is there an insulation board that can/should under the bluestone? Right now, we are planning on having the bluestone sit on 3/4 ply topped with mesh and wet set. All this sits over the main beam, a 6x8 old growth who-knows-what.

Thanks, Folks.

z