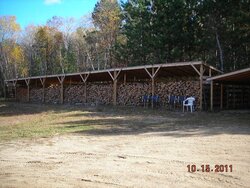

The guys got together to split and load the sheds yesterday. Almost full. Will this be enough to heat my cabin this winter?

Just kidding. Firewood for Deep Portage, which burns about 90 cords each heating season. Mixture of oak, birch, maple and ash.

Just kidding. Firewood for Deep Portage, which burns about 90 cords each heating season. Mixture of oak, birch, maple and ash.