Hi, I'm absolutely new to wood burning. I've been reading threads on this site for almost a year. Gathering as much info as possible to help me make a decision on which direction to go. But to offset my extremely high propane bills to heat my house, I've decided to install a wood burning insert in my masonry fireplace. The wife has said no to a free standing wood stove out in front of the fireplace. I used this fireplace last year and burned wood, obviously it did very little to actually heat the house (although it was nice to watch a burning fire in the fireplace). After reading online and visiting a local fireplace shop. I decide to buy the SBI Century cw2900. For the money, it's a tuff one to beat. It's on back order everywhere, but I managed to pick one up at a Menard's last week. After reading several articles on insulating the firebox (it's an exterior fireplace), I decided to go that direction too. Durock cement board with Roxul insulation behind that. I have a pretty good size fire box, so I can insulate back, sides, bottom and top. Trying to get as much out of this insert as possible. My house is 3000+ sq ft. I know this wood insert is only rated for 2000 sq ft or so, but if it will heat the great room (vaulted), kitchen and dining room I'll be tickled. Going to cut out the damper to fit the liner, instead of ovalizing the liner, and thinking I will go with a pre-insulated one.

So I guess my first question is this, here is the liner I'm wanting to install. http://www.firesidechimneysupply.co...-316ti-stainless-steel-chimney-liner-458.html Has anyone had any experience with this company or this liner? Is it better to buy the liner and install the insulation myself? I do like the idea of it already being insulated.

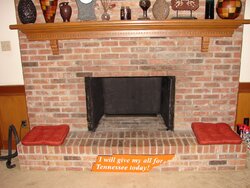

Think I'll try to post some pics of the install as I go

Thanks so much

So I guess my first question is this, here is the liner I'm wanting to install. http://www.firesidechimneysupply.co...-316ti-stainless-steel-chimney-liner-458.html Has anyone had any experience with this company or this liner? Is it better to buy the liner and install the insulation myself? I do like the idea of it already being insulated.

Think I'll try to post some pics of the install as I go

Thanks so much