I am a total newbie at this Gasification boiler stuff. Back in Feb of this year I spoke with two local experts who have installed tons of systems and we sketched out a plan where I would do the work, and they would provide some consulting. However, my time frame didn't seem to match theirs and I can't contact them, so I am left dealing with this on my own. I used to build elaborate luxury homes, but this heating system has me stumped.

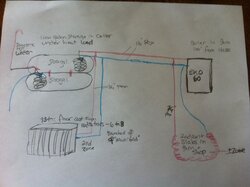

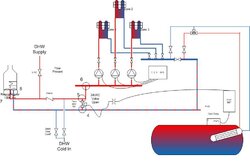

Attached is a sketch--crude at best--of how the plan might work. I've just ordered an Eko-60 to go in the attached barn on the house. It is roughly 100ft from where 1000 gallons of water storage will some day live--if I can find the tanks which will fit in the cellar..... I'm envisioning two 500 gallon propane tanks. The cellar is under the heat load and stays at a pretty stable temperature. My idea is to pump the tanks full of as much heat as I can crank out of the 60--upwards of 190 to 200F. A Coil in the tanks will feed 6-8 cast iron radiators in the house. Another coil in the tanks will heat DHW. Right now I have a failing on-demand propane unit which I will by-pass and plumb the in/out hot-water line right through the coil in the tank, with a mixing valve placed on the hot-water side of the loop to steady temps. I assume I will need the same thing in the radiator zone. Not sure where or how that would go.

Additionally, out in the barn and attached shop I will have a radiant slab which nominally I will heat minimally. The slab can also act as a heat sink/dump to store extra heat or to bleed it off if we have too much going to the tank.

I have seen radiant systems installed. I have run miles of Pex. I can plumb castles. But this "simple" plan has me stumped. Any input would be most welcome! Am I way off base in this? What parts should I consider? Along with the EKO-60 I purchase Cozy Heat's full installation kit, which I assume, for my system, is actually only a partial kit.....

I would love feedback. Thanks.

Attached is a sketch--crude at best--of how the plan might work. I've just ordered an Eko-60 to go in the attached barn on the house. It is roughly 100ft from where 1000 gallons of water storage will some day live--if I can find the tanks which will fit in the cellar..... I'm envisioning two 500 gallon propane tanks. The cellar is under the heat load and stays at a pretty stable temperature. My idea is to pump the tanks full of as much heat as I can crank out of the 60--upwards of 190 to 200F. A Coil in the tanks will feed 6-8 cast iron radiators in the house. Another coil in the tanks will heat DHW. Right now I have a failing on-demand propane unit which I will by-pass and plumb the in/out hot-water line right through the coil in the tank, with a mixing valve placed on the hot-water side of the loop to steady temps. I assume I will need the same thing in the radiator zone. Not sure where or how that would go.

Additionally, out in the barn and attached shop I will have a radiant slab which nominally I will heat minimally. The slab can also act as a heat sink/dump to store extra heat or to bleed it off if we have too much going to the tank.

I have seen radiant systems installed. I have run miles of Pex. I can plumb castles. But this "simple" plan has me stumped. Any input would be most welcome! Am I way off base in this? What parts should I consider? Along with the EKO-60 I purchase Cozy Heat's full installation kit, which I assume, for my system, is actually only a partial kit.....

I would love feedback. Thanks.