Greetings, wood burning enthusiasts! I've been learning from this website and the knowledgeable people on it for years, but haven't had the impulsion to join and post anything until now. I'll try to keep this relatively short, but I always tend to err on the side of more information, rather than less.

My wife and I (and a whole bunch of kids) live in a 2200 sq. ft. "old farmhouse" in northeast Indiana. It's a 2-story house that was built in stages, with each stage a generation or two after the previous. The oldest part was built around 1860, so it's one of the older homes in Whitley County, I'd imagine. At some point in the past, someone blew in insulation from the outside, and it was done fairly well. As part of a major renovation in 2011 (right after we bought it), we gutted the inside and filled in where the insulation had settled and left air pockets. So it's pretty well insulated for what it is. The windows were all replaced with Andersen new-construction windows a couple of years ago.

We added an insert into an existing fireplace about 2 years ago, a Harman 300i. Other than the junk fans that came with it (I warrantied 3 of them in a year before replacing them with aftermarket), it's been good for us, and we have no complaints. The location of the insert in the house is not ideal for maximum heat distribution, however, and needing the fans is a drag when the power goes out. Motivated by a desire to have more reliable heat (with or without power) in a more central location in the house and the ability to cook when there's no power, we're planning to get a Progress Hybrid soon.

There's an old brick chimney that goes from the crawl space that's under most of the house, through the interior of the home, and all the way up through a second story roof. I don't know when the chimney was put in, though its placement suggests it was possibly an exterior chimney until the kitchen was put on. I'd date it somewhere between 80-100 years old, unless it's been redone (which is possible). I was up on the roof yesterday to take the attached pictures. The chimney is about 16 x 22 inches, exterior dimensions, and has what appears to be an 8 x 12 clay liner (6.5 x 10.5 interior dimensions). Judging from what I saw when looking down (and looking at the photo afterwards), the liner looks like it's probably cracked in places, but not in terrible shape. Further likely evidence of cracks/infiltration is the presence of water staining along the upstairs ceiling/wall junction adjacent to the chimney after heavy rains, this despite a brand new roof 3 years ago.

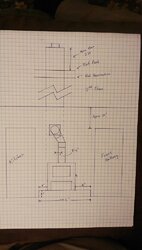

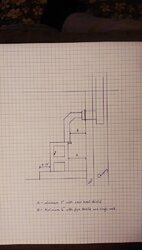

I don't know what was burned into that chimney over the years, but it has 2 round holes that have been cemented in. One hole is in a small cellar that only exists under 2 rooms and houses the propane furnace and water appliances. There may have been an oil burner down there at one point. The other hole is in the dining room on the first floor, about waist high (now behind drywall). Our plan is to build a hearth (with appropriate non-combustible flooring and shielded clearance to the wall) where the blue tape is located in a couple of the attached photos of the dining room. Since the highest plugged hole (that we know of) is waist high or so (just above the wainscoting), we figure we could join the existing chimney about head high or so to maintain clearance to the roughly 8.5 foot ceiling.

Of course, this depends on the chimney being usable. I figure an insulated stainless steel 6-inch liner is pretty much a given, assuming the chimney itself can be trusted. I plan to have 2 or 3 certified chimney sweeps/masons have a look at the chimney and give me opinions and quotes. But I thought I'd show my problem to you folks and get your opinions, too. I have closeup photos of the top, south, east, and west sides, as well as a zoomed-out shot of the north face. Is there anything that stands out to any of you? Red flags, alarm bells? The alternate (and less desirable for several reasons) placement would be on the far wall of the dining room visible in the one photo. That would involve running new stovepipe up through 2 ceilings and a roof. Because of where that would come out upstairs and on the roofline, I'd rather not do it, especially if the existing chimney can be lined and re-purposed.

So, what do you think? I welcome any and all opinions about any stage of the above. Thanks!

My wife and I (and a whole bunch of kids) live in a 2200 sq. ft. "old farmhouse" in northeast Indiana. It's a 2-story house that was built in stages, with each stage a generation or two after the previous. The oldest part was built around 1860, so it's one of the older homes in Whitley County, I'd imagine. At some point in the past, someone blew in insulation from the outside, and it was done fairly well. As part of a major renovation in 2011 (right after we bought it), we gutted the inside and filled in where the insulation had settled and left air pockets. So it's pretty well insulated for what it is. The windows were all replaced with Andersen new-construction windows a couple of years ago.

We added an insert into an existing fireplace about 2 years ago, a Harman 300i. Other than the junk fans that came with it (I warrantied 3 of them in a year before replacing them with aftermarket), it's been good for us, and we have no complaints. The location of the insert in the house is not ideal for maximum heat distribution, however, and needing the fans is a drag when the power goes out. Motivated by a desire to have more reliable heat (with or without power) in a more central location in the house and the ability to cook when there's no power, we're planning to get a Progress Hybrid soon.

There's an old brick chimney that goes from the crawl space that's under most of the house, through the interior of the home, and all the way up through a second story roof. I don't know when the chimney was put in, though its placement suggests it was possibly an exterior chimney until the kitchen was put on. I'd date it somewhere between 80-100 years old, unless it's been redone (which is possible). I was up on the roof yesterday to take the attached pictures. The chimney is about 16 x 22 inches, exterior dimensions, and has what appears to be an 8 x 12 clay liner (6.5 x 10.5 interior dimensions). Judging from what I saw when looking down (and looking at the photo afterwards), the liner looks like it's probably cracked in places, but not in terrible shape. Further likely evidence of cracks/infiltration is the presence of water staining along the upstairs ceiling/wall junction adjacent to the chimney after heavy rains, this despite a brand new roof 3 years ago.

I don't know what was burned into that chimney over the years, but it has 2 round holes that have been cemented in. One hole is in a small cellar that only exists under 2 rooms and houses the propane furnace and water appliances. There may have been an oil burner down there at one point. The other hole is in the dining room on the first floor, about waist high (now behind drywall). Our plan is to build a hearth (with appropriate non-combustible flooring and shielded clearance to the wall) where the blue tape is located in a couple of the attached photos of the dining room. Since the highest plugged hole (that we know of) is waist high or so (just above the wainscoting), we figure we could join the existing chimney about head high or so to maintain clearance to the roughly 8.5 foot ceiling.

Of course, this depends on the chimney being usable. I figure an insulated stainless steel 6-inch liner is pretty much a given, assuming the chimney itself can be trusted. I plan to have 2 or 3 certified chimney sweeps/masons have a look at the chimney and give me opinions and quotes. But I thought I'd show my problem to you folks and get your opinions, too. I have closeup photos of the top, south, east, and west sides, as well as a zoomed-out shot of the north face. Is there anything that stands out to any of you? Red flags, alarm bells? The alternate (and less desirable for several reasons) placement would be on the far wall of the dining room visible in the one photo. That would involve running new stovepipe up through 2 ceilings and a roof. Because of where that would come out upstairs and on the roofline, I'd rather not do it, especially if the existing chimney can be lined and re-purposed.

So, what do you think? I welcome any and all opinions about any stage of the above. Thanks!