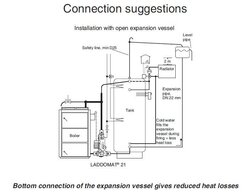

When open expansion tanks (Euro style, vented out on the roof) are discussed on this forum they are often described as "in the attic".

I understand that the system pressure has to be greater than the static head of the system. In other words the 'weight' of the water column from the circulator at the boiler to the very highest point in the system.

If your highest system water was upstairs in the radiant floor tubes and say those tubes are 20ft. above the low point at the boiler circulator in the basement, you would have a static head of a little less that 9psi. As long as system pressure is more than that the circulator can 'circulate' and not have to 'pump' that water upstairs.

How much more does that pressure have to be in the real world?

If only a couple psi, does the open expansion tank need to be all the way up into the attic?. Is it enough to mount it high in a closet on the second floor only a couple or three feet above the same floor that contains those tubes that are the system high point? That would be a little less than 2psi extra. Is that enough?

I'm combing through Siegenthaler's book but I haven't found the answer yet.

I understand that the system pressure has to be greater than the static head of the system. In other words the 'weight' of the water column from the circulator at the boiler to the very highest point in the system.

If your highest system water was upstairs in the radiant floor tubes and say those tubes are 20ft. above the low point at the boiler circulator in the basement, you would have a static head of a little less that 9psi. As long as system pressure is more than that the circulator can 'circulate' and not have to 'pump' that water upstairs.

How much more does that pressure have to be in the real world?

If only a couple psi, does the open expansion tank need to be all the way up into the attic?. Is it enough to mount it high in a closet on the second floor only a couple or three feet above the same floor that contains those tubes that are the system high point? That would be a little less than 2psi extra. Is that enough?

I'm combing through Siegenthaler's book but I haven't found the answer yet.