I have a P68 burning 2nd year. 1st year no problems. This year I'm burning same pellets as last year, this year I am getting a lot of ash building up in the burn pot and not pushing itself down off the burn pot. It piles up several inches. Any Ideas??

P68 Building a lot of ash

- Thread starter snodays700

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

jtakeman

Minister of Fire

Were the pellets stored in a dry location?

Have you completly cleaned the stove since last year?

I would clean the stove and try again or try another new batch(if the stove was cleaned) of pellets just to see if its doing the same.

jay

Have you completly cleaned the stove since last year?

I would clean the stove and try again or try another new batch(if the stove was cleaned) of pellets just to see if its doing the same.

jay

ROBERT F

Minister of Fire

Pellet quaility can vary year to year, and depending on where the were stored, could have absorbed moisture.

I have burned some from last year and some that I have bought new this year still the same. I have cleaned it before I statred this year, I guess I can clean it again. This wouldn't have anything to do with any of the settings?

jtakeman

Minister of Fire

snodays700 said:I have burned some from last year and some that I have bought new this year still the same. I have cleaned it before I statred this year, I guess I can clean it again. This wouldn't have anything to do with any of the settings?

If you are burning at the same settings as last year. I would say no.

Sounds like it maybe an air issue with the stove. You did have the vent pipe cleaned?

How is the holes in the burn pot?

johnny1720

Burning Hunk

If you are getting a bunch of ash you might want to check your door seals and ash pan seals for leak. If you are pulling air in a bunch of air from other places than the air wash an under the burn pot, you could get getting an incomplete burn.

It could be your pellets but take a look at your seals first. I have seen them go bad especially if you are hitting them with the shop vac.

Johnny

It could be your pellets but take a look at your seals first. I have seen them go bad especially if you are hitting them with the shop vac.

Johnny

summit

Minister of Fire

what kind of pellets, and how long has it been since the thing was cleaned (pipe and all)? how's the flame look? is it lazier than normal? taking a long time to ignite?

johnny1720

Burning Hunk

snodays700 said:What do recomend if the flame is lazy? Also what do i look for on the door gasket.

If the stove is burning lazy double check that you have cleaned everything out! Search you tube for videos on how to clean your stove. To do a quick check on the door and ash pan seals do this, take a candle and light it and run it around the door and see if the flame dances. Its a quick way to check. Then if it is dancing you can do the dollar bill test.

Good Luck.

Elad

Member

I too have the same problem...

1st time user of a pellet stove I bought last spring on sale (p68) so I came here to see if there's a solution.

It worked great on first use of 1 1/2 days. No buildup with feed at 3. Then my auger drive motor gearbox failed.

Appearently Harmon is aware of a few defective drives.

3wks later am finally up n running...

Since then and 1 week of usage now of the p68, I get clinkers building up at the top to the edge and they are too big

& heavy to get pushed out. Have to manually remove em or flames get directed at the glass instead of up due to the

buildup blocking.

I did a cleanout of the firebox (under-inside too) and already had carbon buildup in the pot. 1 week?

Ash pan almost 1/2 full too which surprised me.

Some pellets get blown out of the pot even (very few) so there's plenty of air moving, just getting clinkers made as

whats left of the pellets melt after burning.

Pellets are stored in basement in another room (stove in center of basement) with a dehumidifier in the pellet room so

no moisture problems there. House humidity at 15 so guite dry... I carried 3 tons down into the room - man thats a leg

killer!

Another friend bought the same premium hardwood pellets (from NorthernTool.com on sale $4.49ea @ 1 ton) but he only

has fines/dust and no clinkers building up like I do (he has different stove though).

I did notice that a higher setting (4 1/2) does helped a lot to reduced this problem (wow - man that is so hot up at

4.5. Really cranks out the heat), but I still have it. More so when stove slows down as temp gets close to settings.

Am also burning a bag / 12 hrs so its using a lot of fuel

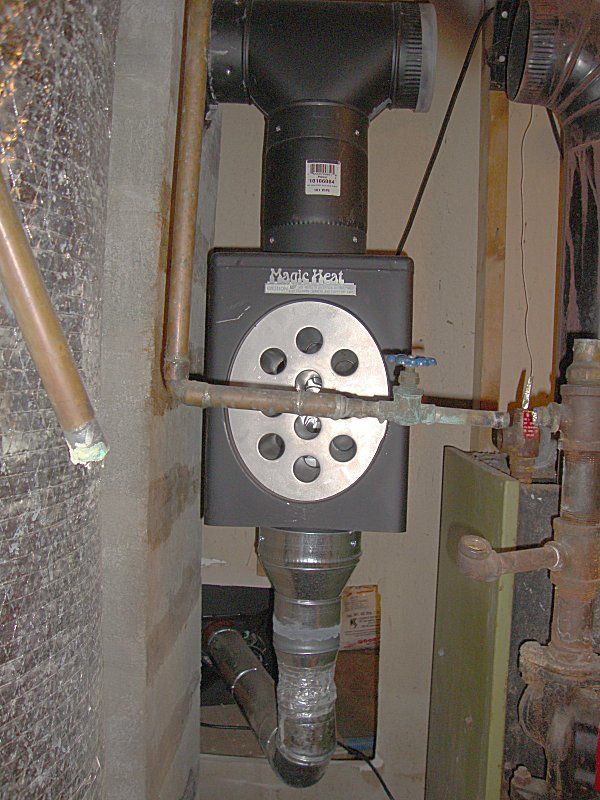

Exhust is piped 2' of 3" pipe then I use a reducer to 6" then into a heat exchanger (10 tubes - NorthernTool com)

then into a 6" stove T then to the chimney and total lenght is only 4'. I even have a plastic cover at the end of the

T that does not melt even. Heat exchanger does its job well

There is always suction even with no heat running in the chimney with 8" flue (split level house).

So, what gives ?

These clinkers will crumble easly

A shot of them clinkers after its been 4 hrs since I last cleaned them out

Moved out of the way the fuel oil hot water furnace for access installing exhaust of P68

Notice the plastic cover at top end of Tee - does not melt and vacume keeps it in place

Video in action simular to pic#2

[youtube]http://www.youtube.com/SamaritanElad[/youtube]

Also am posting this problem that another has here: https://www.hearth.com/econtent/index.php/forums/viewthread/44798/

1st time user of a pellet stove I bought last spring on sale (p68) so I came here to see if there's a solution.

It worked great on first use of 1 1/2 days. No buildup with feed at 3. Then my auger drive motor gearbox failed.

Appearently Harmon is aware of a few defective drives.

3wks later am finally up n running...

Since then and 1 week of usage now of the p68, I get clinkers building up at the top to the edge and they are too big

& heavy to get pushed out. Have to manually remove em or flames get directed at the glass instead of up due to the

buildup blocking.

I did a cleanout of the firebox (under-inside too) and already had carbon buildup in the pot. 1 week?

Ash pan almost 1/2 full too which surprised me.

Some pellets get blown out of the pot even (very few) so there's plenty of air moving, just getting clinkers made as

whats left of the pellets melt after burning.

Pellets are stored in basement in another room (stove in center of basement) with a dehumidifier in the pellet room so

no moisture problems there. House humidity at 15 so guite dry... I carried 3 tons down into the room - man thats a leg

killer!

Another friend bought the same premium hardwood pellets (from NorthernTool.com on sale $4.49ea @ 1 ton) but he only

has fines/dust and no clinkers building up like I do (he has different stove though).

I did notice that a higher setting (4 1/2) does helped a lot to reduced this problem (wow - man that is so hot up at

4.5. Really cranks out the heat), but I still have it. More so when stove slows down as temp gets close to settings.

Am also burning a bag / 12 hrs so its using a lot of fuel

Exhust is piped 2' of 3" pipe then I use a reducer to 6" then into a heat exchanger (10 tubes - NorthernTool com)

then into a 6" stove T then to the chimney and total lenght is only 4'. I even have a plastic cover at the end of the

T that does not melt even. Heat exchanger does its job well

There is always suction even with no heat running in the chimney with 8" flue (split level house).

So, what gives ?

These clinkers will crumble easly

A shot of them clinkers after its been 4 hrs since I last cleaned them out

Moved out of the way the fuel oil hot water furnace for access installing exhaust of P68

Notice the plastic cover at top end of Tee - does not melt and vacume keeps it in place

Video in action simular to pic#2

[youtube]http://www.youtube.com/SamaritanElad[/youtube]

Also am posting this problem that another has here: https://www.hearth.com/econtent/index.php/forums/viewthread/44798/

summit

Minister of Fire

those clinkers are a result of the pellet, not the stove: they are probably loaded with dirt, or construction debris, giving you those nice hard clinkers... also, i would reccomend getting a metal cap for your tee (and please put some screws in it to secure it!)

summit said:those clinkers are a result of the pellet, not the stove: they are probably loaded with dirt, or construction debris, giving you those nice hard clinkers... also, i would reccomend getting a metal cap for your tee (and please put some screws in it to secure it!)

Not necessarily true. A clinker is created when minerals in the ash actually begin to melt and fuse together in the burn pot . Pellet stoves operate near the combustion temperatures that are required to melt ash. Once the ash begins to melt it may obstruct the air holes of the incoming air and affect the proper mix of air and fuel. Incorrect adjustment of the air to fuel ratio can greatly increase the likelihoods of clinker formation. This is due to the stoves inability to adequately burn the excess fuel and remove the excess ash that is building up in the burn pot. Conditions of combustion effect the composition and amount of residue ash- higher burn temps will reduce ash yeild.

Since the pellets being burned are the same as last season, without clinkers, something must have changed with the burn conditions of the stove.

L

Lousyweather

Guest

BDPVT said:summit said:those clinkers are a result of the pellet, not the stove: they are probably loaded with dirt, or construction debris, giving you those nice hard clinkers... also, i would reccomend getting a metal cap for your tee (and please put some screws in it to secure it!)

Not necessarily true. A clinker is created when minerals in the ash actually begin to melt and fuse together in the burn pot . Pellet stoves operate near the combustion temperatures that are required to melt ash. Once the ash begins to melt it may obstruct the air holes of the incoming air and affect the proper mix of air and fuel. Incorrect adjustment of the air to fuel ratio can greatly increase the likelihoods of clinker formation. This is due to the stoves inability to adequately burn the excess fuel and remove the excess ash that is building up in the burn pot. Conditions of combustion effect the composition and amount of residue ash- higher burn temps will reduce ash yeild.

Since the pellets being burned are the same as last season, without clinkers, something must have changed with the burn conditions of the stove.

minerals, primarily silica. It IS usually a function of the pellet, specifically chloride content......an elevated chloride content will cause the fusion temperature (melting point, if you will), to be reduced, actually causing fusion of these minerals, in the burn pot. The clinkers here can go from gritty, "sandy feeling", to a clump of gritty, glassy product. thats what appears to me you are seeing......easy fix.......go buy a few bags of different pellets, see if it alleviates the issue.

Lousyweather said:BDPVT said:summit said:those clinkers are a result of the pellet, not the stove: they are probably loaded with dirt, or construction debris, giving you those nice hard clinkers... also, i would reccomend getting a metal cap for your tee (and please put some screws in it to secure it!)

Not necessarily true. A clinker is created when minerals in the ash actually begin to melt and fuse together in the burn pot . Pellet stoves operate near the combustion temperatures that are required to melt ash. Once the ash begins to melt it may obstruct the air holes of the incoming air and affect the proper mix of air and fuel. Incorrect adjustment of the air to fuel ratio can greatly increase the likelihoods of clinker formation. This is due to the stoves inability to adequately burn the excess fuel and remove the excess ash that is building up in the burn pot. Conditions of combustion effect the composition and amount of residue ash- higher burn temps will reduce ash yeild.

Since the pellets being burned are the same as last season, without clinkers, something must have changed with the burn conditions of the stove.

minerals, primarily silica. It IS usually a function of the pellet, specifically chloride content......an elevated chloride content will cause the fusion temperature (melting point, if you will), to be reduced, actually causing fusion of these minerals, in the burn pot. The clinkers here can go from gritty, "sandy feeling", to a clump of gritty, glassy product. thats what appears to me you are seeing......easy fix.......go buy a few bags of different pellets, see if it alleviates the issue.

I'm not arguing the chemical content of the pellets. The quality of the fuel is very important. But the poster stated that he has lots of ash and clinkers and a lazy flame compared to last season while burning the same pellets. So what has changed? Maybe adjust the burn conditions of the stove and go from there. All Im saying is that swapping pellets without checking burn conditions may not yeild any results.

SmokeyTheBear

Minister of Fire

Looks like there could be a good place for ash build up right where the exhaust from the stove turns up into that flue cooler magic heat thingy. Might want to turn the stove off and take a real good look in there. Both up and downwards .... never know.

That would cause a bit of a burn problem if full of ash.

BTW trees are funny sort of like water, they suck up or entrap all kinds of nasty inorganic stuff that no burn and cause funnies to happen. But first I'd check that stack, heaven only knows you might have a family of raccoons living in your chimney.

That would cause a bit of a burn problem if full of ash.

BTW trees are funny sort of like water, they suck up or entrap all kinds of nasty inorganic stuff that no burn and cause funnies to happen. But first I'd check that stack, heaven only knows you might have a family of raccoons living in your chimney.

Elad

Member

lol...

This is a new install. Problem started on 3rd day of use ( after new auger motor installed).

Dealer's technician looked at the pics I have posted in these forums (located in another post by jerf Title: "Problems with Harman P68"

which shows more pics of the clinkers and another video.

He (jerf) mention the same problems after his motor was replaced. Interesting... https://www.hearth.com/econtent/index.php/forums/viewthread/44798/

Anyway, the tech said that it appears to be too much airflow and instructed me to lower the trimpot a bit (controls combustion motor speed).

I ended up fully turned down and only notice a small effect. Flame line did move up a bit.

Tech also thinks too much flue vacuum. I removed the cap and also opened the chimney's trap clean out door at bottom of chimney.

Very little draft at the Tee now but enough that no smoke comes out. Tested with a lighter and observed the flame still pulling into the chimney.

The firebox flame line is suppose to be 1" from the edge (that's at the 1st line of holes in pot). It has moved up a bit from lowering the trimpot, but still 2" away at 2nd or 3rd hole line & still getting them clinkers.

Am more thinking it may be the controller board, or maybe the egt probe sending wrong signal. Combustion motor barely slows down in test mode.

Seems to be too strong an airflow in the firebox all the time.

1st day of use, the chimney was cold, although it always has a draft. So warm now it does draft more.

Stove worked good for the 1st 1 1/2 days...

Something happened when new drive motor was replaced...

I now notice its more hotter on 3-4 than 5-6 settings. Tech wanted it at 4 1/2. I turned it down to 3 1/2 now and flame is hotter. Seem to be more sooty at 5-6 settings.

Am 38miles from the dealer so with their approval, am trying to self repair as I only have Thr & Fri off to be there for em.

But, may have to get em out here again as this is not working right...

This is a new install. Problem started on 3rd day of use ( after new auger motor installed).

Dealer's technician looked at the pics I have posted in these forums (located in another post by jerf Title: "Problems with Harman P68"

which shows more pics of the clinkers and another video.

He (jerf) mention the same problems after his motor was replaced. Interesting... https://www.hearth.com/econtent/index.php/forums/viewthread/44798/

Anyway, the tech said that it appears to be too much airflow and instructed me to lower the trimpot a bit (controls combustion motor speed).

I ended up fully turned down and only notice a small effect. Flame line did move up a bit.

Tech also thinks too much flue vacuum. I removed the cap and also opened the chimney's trap clean out door at bottom of chimney.

Very little draft at the Tee now but enough that no smoke comes out. Tested with a lighter and observed the flame still pulling into the chimney.

The firebox flame line is suppose to be 1" from the edge (that's at the 1st line of holes in pot). It has moved up a bit from lowering the trimpot, but still 2" away at 2nd or 3rd hole line & still getting them clinkers.

Am more thinking it may be the controller board, or maybe the egt probe sending wrong signal. Combustion motor barely slows down in test mode.

Seems to be too strong an airflow in the firebox all the time.

1st day of use, the chimney was cold, although it always has a draft. So warm now it does draft more.

Stove worked good for the 1st 1 1/2 days...

Something happened when new drive motor was replaced...

I now notice its more hotter on 3-4 than 5-6 settings. Tech wanted it at 4 1/2. I turned it down to 3 1/2 now and flame is hotter. Seem to be more sooty at 5-6 settings.

Am 38miles from the dealer so with their approval, am trying to self repair as I only have Thr & Fri off to be there for em.

But, may have to get em out here again as this is not working right...

L

Lousyweather

Guest

Elad-

the pictures you posted (of the clinkers- pictures are always MOST helpful! thanks!), are almost certainly created by the pellet quality rather than a setting on your stove. You can fidget with the settings to change where your fire burns, etc. As I said, get 5 bags of DIFFERENT pellets and try them. The outcome should be self-evident.

the pictures you posted (of the clinkers- pictures are always MOST helpful! thanks!), are almost certainly created by the pellet quality rather than a setting on your stove. You can fidget with the settings to change where your fire burns, etc. As I said, get 5 bags of DIFFERENT pellets and try them. The outcome should be self-evident.

SmokeyTheBear

Minister of Fire

clinkers = temperature + inorganic ash amount + correct moisture + the time at the correct conditions.

If your stove had a "fast" auger and then got a "slow" one the time constraint above would be impacted.

Anything the removes the ash or reduces the amount of ash would change the ash content constraint above. This can be air flow or pellet quality as Lousyweather has repeatedly mentioned. I'll let you discover what impacts air flow.

Pellet quality also impacts the very small amount of moisture required in the above constraints, the lower the moisture content the less you'll be able to sinter that lovely ash and form a big honking clinker like this 4.5 " by 2.5 " by 1.5 " :

If your stove had a "fast" auger and then got a "slow" one the time constraint above would be impacted.

Anything the removes the ash or reduces the amount of ash would change the ash content constraint above. This can be air flow or pellet quality as Lousyweather has repeatedly mentioned. I'll let you discover what impacts air flow.

Pellet quality also impacts the very small amount of moisture required in the above constraints, the lower the moisture content the less you'll be able to sinter that lovely ash and form a big honking clinker like this 4.5 " by 2.5 " by 1.5 " :

Attachments

Elad

Member

Your Right!

Am sure its not moisture, but there's something wrong with them pellets:

Starlite Premium hardwood from KoetterSmith.com out of IN

I tried 2 other brands and both of them work great - no clinkers at all.

Lumber Jack brand and Menards; Indeck Energy pellets. Both out of Wi

Problems Solved... Strange though that my friend uses them Starlites without any problems in his St Croix stove. But he has some kind of scraper plate that slowly moves in the firebox...

Thanks All... I'll just burn the rest of them (2 1/2 tons left) off at top speed setting.

I contacted the makers of Starlite with pics and they responded with this:

Dale,

I have sent your information on to our plant manager/owner to see what their thoughts are. Typically when we see any clinker forming like yours it is because the silica content is too high. This can happen when a loader operator tries to scrape the ground to hard to load our “hog” (the initial grinding device) before it goes into the hammer mill to reduce the overall sizing to fiber length that can then be dried.

I’ll keep you posted

Stephen J. Magee

Sales & Marketing Manager

Koetter & Smith, Inc.

Office-812-923-5111 x124

Cell- 502-396-5432

www.koettersmith.com

Am sure its not moisture, but there's something wrong with them pellets:

Starlite Premium hardwood from KoetterSmith.com out of IN

I tried 2 other brands and both of them work great - no clinkers at all.

Lumber Jack brand and Menards; Indeck Energy pellets. Both out of Wi

Problems Solved... Strange though that my friend uses them Starlites without any problems in his St Croix stove. But he has some kind of scraper plate that slowly moves in the firebox...

Thanks All... I'll just burn the rest of them (2 1/2 tons left) off at top speed setting.

I contacted the makers of Starlite with pics and they responded with this:

Dale,

I have sent your information on to our plant manager/owner to see what their thoughts are. Typically when we see any clinker forming like yours it is because the silica content is too high. This can happen when a loader operator tries to scrape the ground to hard to load our “hog” (the initial grinding device) before it goes into the hammer mill to reduce the overall sizing to fiber length that can then be dried.

I’ll keep you posted

Stephen J. Magee

Sales & Marketing Manager

Koetter & Smith, Inc.

Office-812-923-5111 x124

Cell- 502-396-5432

www.koettersmith.com

- Status

- Not open for further replies.

Similar threads

- Replies

- 7

- Views

- 709

- Replies

- 2

- Views

- 638

- Replies

- 13

- Views

- 885

- Replies

- 2

- Views

- 408