Two scenarios that might be challenging from my perspective:

1. If your boiler buddy is fully heated and your boiler is off, then a call for heat comes from, say your fan coil heaters. How do they draw heat out of the boiler buddy without having to pull it through your pellet boiler? Ideally the pellet boiler would be on an isolated circuit so water only flows through it when it's actively burning.

2. When the boiler is running, hot water is leaving the boiler and feeding into the distribution emitters. Their cold return water then goes into the top of the boiler buddy. What you want to strive for is maintaining heat stratification in your buffer tank - hot on top, cold on the bottom - it allows for more efficient use of the available BTUs in that tank. By dumping that cold return water in the top of your tank you destroy that stratification in the tank. Ideally you would return the cold water to the bottom of the tank.

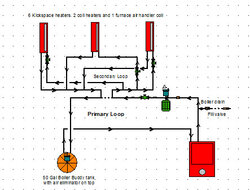

I would use the tank as a hydraulic separator between your boiler and your secondary loops. Think of it as the middleman. The boiler buddy should have 4 taps, two top, two bottom. The boiler supply goes into one of the top taps and the zone supplies go out the other top tap. The zone returns go in one of the bottom taps, and the boiler return in the other. This keeps the cold water low and the hot water high. It also allows the zones to pull hot water from the tank without immediately firing off the boiler. An aquastat in the control well of the tank tells the boiler when its heat is becoming depleted and tells it to fire up and recharge the tank.

Lots of subtle permutations on this, but that's the basic config. Take a look at the tank sketch on Boiler Buddy's home page to see the general concept:

http://www.boilerbuddy.com/ Look at some of the pics in their photo gallery - they show it very nicely.