Ok so I need Help with Ideas to fix the 2 problems I have with this stove, both I'm pretty sure are heat related!

#1 solution the stove runs perfectly fine with both side covers taken off (gets more airflow to the back) but it's louder that way. doesn't look to good either!

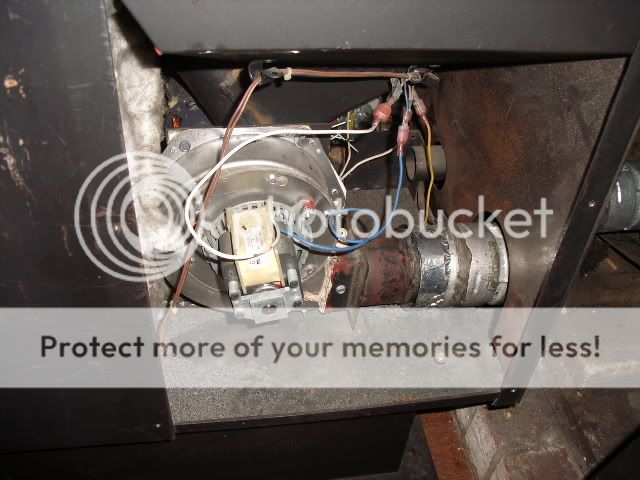

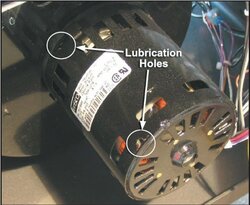

The problems. Today I put the left side cover on, the one over by the blower motor,(exhaust) it took all day but eventually the motor over heated and shut off, the whole house filled with smoke and the stove turned off.

let it all cool down, took the side back off and turned it back on. Runs like a champ!

The other side is where the thermocouple is, If I put that side together, that over heats also turning off the stove !!

!!

What can I do to help keep things cool back there? would more insulation help? to me it seams like radiant heat, I would think just insulating everything would not help. Eventually everything will heat soak again?

I could maybe add a fan to one of the sides too pull the hot air out but this thing didn't come that way so I shouldn't need too!

Help, I'm open to any suggestions

Thanks

#1 solution the stove runs perfectly fine with both side covers taken off (gets more airflow to the back) but it's louder that way. doesn't look to good either!

The problems. Today I put the left side cover on, the one over by the blower motor,(exhaust) it took all day but eventually the motor over heated and shut off, the whole house filled with smoke and the stove turned off.

let it all cool down, took the side back off and turned it back on. Runs like a champ!

The other side is where the thermocouple is, If I put that side together, that over heats also turning off the stove

!!

!!What can I do to help keep things cool back there? would more insulation help? to me it seams like radiant heat, I would think just insulating everything would not help. Eventually everything will heat soak again?

I could maybe add a fan to one of the sides too pull the hot air out but this thing didn't come that way so I shouldn't need too!

Help, I'm open to any suggestions

Thanks