Hi gang.

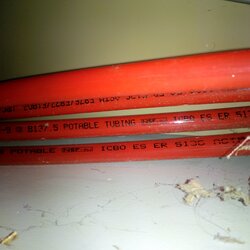

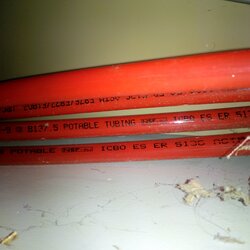

I put an addition on my home about 13 years ago and had a plumber install radiant floor in the basement portion. It was fueled by my oil fired hot water tank. I would now like to hook it into my boiler system but am unsure about whether the plumber installed the oxygen barrier pex in the concrete. Here is what it looks like. Is it appropriate?

I put an addition on my home about 13 years ago and had a plumber install radiant floor in the basement portion. It was fueled by my oil fired hot water tank. I would now like to hook it into my boiler system but am unsure about whether the plumber installed the oxygen barrier pex in the concrete. Here is what it looks like. Is it appropriate?