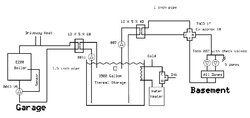

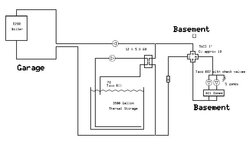

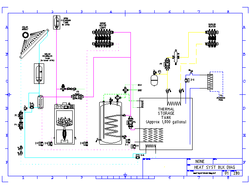

Here is an updated diagram, much simplier than previous designs. What do you think?

I put a variable speed pump at the boiler. It will slow down if the boiler temp drops down below 150 in order to give the boiler some time to catch up and get up to temperature. VS pumps are expensive, but not as expensive as a standard pump and a big mixing valve for boiler protection.

This is an in-floor radiant system, so I should be fine even when storage temperatures drop down below about 110. I used a mixing valve with a Cv of 9.3 in order to get enough hot water injection when my storage temp is very low. If storage is 110, water to the system will be 100F (10F drop across the heat exchanger). Assuming there is a 10F delta across the heating zones, this will still yield 93,000 BTU per hour to heat the house. If my storage is 180F, I will have 418,000 BTU available to heat the house ( ). Any problems here?

). Any problems here?

DHW will be a problem when the storage is below about 130, so I am not relying on wood to fully heat my DHW. I am just using the storage tank to pre-heat the DHW. If anyone can think of a better system, I am all ears.

Thanks for your help!

Andrew

I put a variable speed pump at the boiler. It will slow down if the boiler temp drops down below 150 in order to give the boiler some time to catch up and get up to temperature. VS pumps are expensive, but not as expensive as a standard pump and a big mixing valve for boiler protection.

This is an in-floor radiant system, so I should be fine even when storage temperatures drop down below about 110. I used a mixing valve with a Cv of 9.3 in order to get enough hot water injection when my storage temp is very low. If storage is 110, water to the system will be 100F (10F drop across the heat exchanger). Assuming there is a 10F delta across the heating zones, this will still yield 93,000 BTU per hour to heat the house. If my storage is 180F, I will have 418,000 BTU available to heat the house (

). Any problems here?

). Any problems here? DHW will be a problem when the storage is below about 130, so I am not relying on wood to fully heat my DHW. I am just using the storage tank to pre-heat the DHW. If anyone can think of a better system, I am all ears.

Thanks for your help!

Andrew