Is anyone here using a flat plate HX instead of the normal copper coil exchangers in a conventional indoor application? If so, what are the pros and cons? I'm expecting delivery next week of a Tarm Solo 40. I plan to go without storage this year but I may change my mind. I'll probably go with a STSS 957 gallon tank. Very convenient but expensive.

Plate HX

- Thread starter chuck172

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Nofossil

Moderator Emeritus

chuck172 said:Is anyone here using a flat plate HX instead of the normal copper coil exchangers in a conventional indoor application? If so, what are the pros and cons? I'm expecting delivery next week of a Tarm Solo 40. I plan to go without storage this year but I may change my mind. I'll probably go with a STSS 957 gallon tank. Very convenient but expensive.

I'm not using one yet but I will be soon. In my case, it will be to transfer heat from a direct vent propane tankless hot water heater to my indirect DHW storage tank. I think the advantages are excellent heat transfer performance, relatively low cost, and a compact package. Disadvantages: primarily, the fact that you need another circulator that has to run whenever you want heat. Much more difficult to plumb so that you can maintain stratification in your storage. Difficult to accurately predict performance in real-world conditions.

Others with actual experience may have differing insights.....

"Difficult to accurately predict performance in real-world conditions."

Right, that's why I'd like to know if anyone is successfully using it in my particular application. In theory it seems to have some advantages. Most people use the copper coils, but the price of copper has really shot up. A 180' coil goes for $1,150.00. I think I'd need 3. Add that pricetag to the tank, $2,285.00, and were talking big bucks here.

Right, that's why I'd like to know if anyone is successfully using it in my particular application. In theory it seems to have some advantages. Most people use the copper coils, but the price of copper has really shot up. A 180' coil goes for $1,150.00. I think I'd need 3. Add that pricetag to the tank, $2,285.00, and were talking big bucks here.

free75degrees

New Member

I am making my own copper coils from 10 foot 1/2" hard tubes using a conduit bender to coil them and 45* joints to connect them into large coils. They cost $15 per 10 feet, so they turn out to be more expensive than a plate HX but MUCH less than the prices from STSS.

I think the coils from STSS are 3/4"

You can buy 100' 3/4 L copper tubing rolls for $355.00. That may be a good way to go.

You can buy 100' 3/4 L copper tubing rolls for $355.00. That may be a good way to go.

Willman

Minister of Fire

Have you ever used a swager to expand the pipe to accept itself ?I am making my own copper coils from 10 foot 1/2” hard tubes using a conduit bender to coil them and 45* joints to connect them into large coils. They cost $15 per 10 feet, so they turn out to be more expensive than a plate HX but MUCH less than the prices from STSS.

Will

Redox

Minister of Fire

Willman said:Have you ever used a swager to expand the pipe to accept itself ?I am making my own copper coils from 10 foot 1/2” hard tubes using a conduit bender to coil them and 45* joints to connect them into large coils. They cost $15 per 10 feet, so they turn out to be more expensive than a plate HX but MUCH less than the prices from STSS.

Will

Used to use them all the time in the refrigeration business. It works well on soft copper, but I suppose you could anneal hard copper and make it work. We used to braze the lines together and never had a problem. Not as pretty as a clean fitting, but cheaper and more reliable.

Chris

WoodNotOil

Minister of Fire

I plan to use a flat plate hx in the heat storage I am making. It is used successfully delivering heat from OWBs to the system in a house, so I assume it could be successful in transferring to storage. I read in other posts that one problem is that you can only get the tank within about 10* of the boiler temp. Not sure if coils do not have this problem.

Nofossil - How does the stratification problem work? I assume water is drawn out of the top of the tank and returned to the bottom. Since heat rises shouldn't it automatically stratify? Is efficiency lost in the movement of water through the tank? I assume coils would heat the stratified layers and therefore the heat does not have to rise.

Nofossil - How does the stratification problem work? I assume water is drawn out of the top of the tank and returned to the bottom. Since heat rises shouldn't it automatically stratify? Is efficiency lost in the movement of water through the tank? I assume coils would heat the stratified layers and therefore the heat does not have to rise.

Nofossil

Moderator Emeritus

WoodNotOil said:I plan to use a flat plate hx in the heat storage I am making. It is used successfully delivering heat from OWBs to the system in a house, so I assume it could be successful in transferring to storage. I read in other posts that one problem is that you can only get the tank within about 10* of the boiler temp. Not sure if coils do not have this problem.

Nofossil - How does the stratification problem work? I assume water is drawn out of the top of the tank and returned to the bottom. Since heat rises shouldn't it automatically stratify? Is efficiency lost in the movement of water through the tank? I assume coils would heat the stratified layers and therefore the heat does not have to rise.

The 10 degree problem is common to all heat exchangers. Oversizing can make it an 8 degree problem, but it's really tough to make it a 5 degree problem.

The ideal way to maximize stratification is to draw water from the bottom and return it to the top when heating the tank. You then want to draw from the top and return to the bottom when extracting heat from the tank. I have a diagram of how I do it with an internal coil on my site. To do otherwise mixes the tank. You might get a bit of stratification, but nowhere near as much, and without the sharp thermocline that you want.

Being able to reverse flow direction with a flat plate requires either two heat exchangers and pumps, fancy plumbing with expensive valves, or some wizardry that I haven't figured out yet.

So is it the general consensus here to go with the traditional copper coil heat exchangers instead of the plate HX's? Remember I'm talking basic residential heat storage here.

Nofossil

Moderator Emeritus

chuck172 said:So is it the general consensus here to go with the traditional copper coil heat exchangers instead of the plate HX's? Remember I'm talking basic residential heat storage here.

I doubt there's anything approaching a consensus. Heck, I can't even reach a consensus with myself. For the cost of copper, you might be better off with two plate HX, each with a circulator: 1 top to bottom, and one bottom to top. Or one plate hx, two circs, and two zone valves. I did coils when copper was cheap.

muleman51

Member

I'm in the same predicament, do I build storage or not? I figure I'll have aleast three grand in tank and coils or exchangers and pumps. Or do I just give up and buy a Garn, take the whoopin and have it all in one unit. Anyone want to buy a slightly used Adobe.

I think as we get closer to the heating season this year, the storage topic will get lots of attention. There's lots of money to be saved by building your own copper coil, or going with the flat plate heat exchangers. Companies like STSS are really taking advantage of the situation. I think if we pool our knowledge and experience, we can do alright.

jebatty

Minister of Fire

Apologize for the duplication, but . . .

jebatty said:I remain puzzled over the fascination with large (STSS style) coil hx's when the low relative price and high efficiency of plate hx's is so well known. Without repeating my prior posts on this topic, all I will add is that the cost of an extra circ pump appears to be the primary objection. Addressing that objection:

1) Plate hx on ebay about $225.

2) Taco 007 on ebay about $50.

3) Elec draw of 007 is about 85 watts. Assuming 6 hrs/day, which for my extreme northern clime and heating 1000 gal of storage would be average (some days longer, some shorter), that amounts to 15kwh/mo, or $1.40/mo at our $0.09 rate.

Chuck172 reports cost of copper (I assume 3/4", which I think is STSS) to make your own coils to duplicate STSS: 540’ copper- $1,650.00.

The math: $1650 - $225 - $50 = $1375 / $1.40 = 982 mos = 8.5 years of operation before payback on coils for my installation. If I take that $1375 and invest it at 3% (on average can do much better than this), that is $41.25/hr, and my electric cost (generous) is $1.40 x 6 = $8.40 per year (six months of heating).

Simplicity and time: a plate hx over making coils is no contest.

Seems to be that the cost and operation of an extra circ pump as an objection to the plate hx is based on erroneous assumptions.

jebatty

Minister of Fire

Much more difficult to plumb so that you can maintain stratification in your storage.

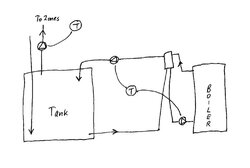

Would never try to match nofo's innovative plumbing. Yet to me, the basic plate hx setup is very simple. In the diagram, the boiler and plate hx circ pumps are controlled by the same aquastat/sensor, so if boiler circ is operating, then plate hx circ is operating. The zone circ is separately controlled. Obviously, this is a concept drawing.

In my setup, the boiler circ is set on at 155F, so the boiler comes up to temp as quickly as possible. Once it is up to temp, it never drops below this setting until the fire is burned out, so all boiler produced heat is transferred to the tank. I also have these pumps on a timer, so if tank return is greater that 155F, then circ pumps shut down anyway when the fire is out.

Attachments

free75degrees

New Member

jebatty - are your zones drawing directly from the storage tank water? If so do you heat exclusively with wood, or do you also have fossil? If you have fossil, how does it tie into the zones?

jebatty

Minister of Fire

free75degrees said:jebatty - are your zones drawing directly from the storage tank water? If so do you heat exclusively with wood, or do you also have fossil? If you have fossil, how does it tie into the zones?

"yes," but ... I actually have no zones, as I heat my shop by radiation from the storage tank itself. If I had zones, I would heat directly from storage with a bypass to get immediate heat from either the boiler or tank side of the hx if the tank itself was not up to sufficient temp. In normal circumstances I would think of the tank as the "boiler supply" and plumb accordingly.

I heat exclusively with wood. There are a variety of posts on series/parallel plumbing, with and without storage, to get ideas on how to use a another boiler and a wood boiler.

WoodNotOil

Minister of Fire

I still plan to go with flat plate for my storage tank because of cost. I had planned to do it with only one hx always drawing from the top of the tank and returning to the bottom. However, Nofossils comments on stratification are causing me to think about adding another exchange to heat the tank from bottom to top as he suggested. Even with two exchanges and pumps the cost is still lower than building copper coils. The exchanges I am looking at cost $200 and the pumps are $50. That brings the cost to $500 and I don't have long coils to build. Do people agree that the stratification issue warrants the additional hx plate or would it work without it? I am heating the tank with my tarm 40 and drawing from the tank to heat my oil boiler which supplies zones and DHW.

free75degrees

New Member

WoodNotOil

Minister of Fire

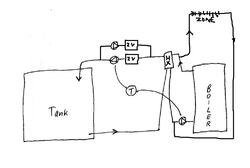

free75degrees - I was considering something like your drawing with one hx, two pumps, zone valves, etc. However, my concern was that I would need a complicated control system so that both pumps would not try to run at the same time. Is there a simple way of doing that?

free75degrees

New Member

I haven't thought about it much, but there is probably a way to hard wire it so they both can't run. For instance, you might be able to use a 3 way relay so that when one pump is on, the other one has to be off. A similar thing could be done with the zone valves.WoodNotOil said:free75degrees - I was considering something like your drawing with one hx, two pumps, zone valves, etc. However, my concern was that I would need a complicated control system so that both pumps would not try to run at the same time. Is there a simple way of doing that?

Nofossil

Moderator Emeritus

WoodNotOil said:free75degrees - I was considering something like your drawing with one hx, two pumps, zone valves, etc. However, my concern was that I would need a complicated control system so that both pumps would not try to run at the same time. Is there a simple way of doing that?

If I didn't have my complicated controller, I'd have a simple relay that was connected to the boiler circ. If the boiler circ is on, then no power goes to the tank recovery circ. If the boiler circ is off, then no power can go to the tank charging circ. You might have additional logic that would prevent the circs from coming on if there were no demand, but denying power based on the boiler circ would be a good start and fairly simple to do. Use a single pole double throw relay (SPDT) so that the common is connected to one output or the other, depending on whether the relay is energized.

In the schematic beow, the 'stage 1 relay' chooses either the stage 1 or stage 2 thermostat contacts to energize the demand coil. This is an example of an SPDT relay. In your case, you could route power to one of two circulators that way.

WoodNotOil

Minister of Fire

Does anyone know if you can pump water through a pump in the opposite direction when it is off? If so, free75degree's pencil drawing could be simplified further by having one pump on the top line from the tank and one on the bottom line of the tank pointing in opposite directions. So long as they were on a relay and couldn't run at the same time and so long as water can reverse through the pump without causing damage woud it work? Just a thought.

Redox

Minister of Fire

WoodNotOil said:Does anyone know if you can pump water through a pump in the opposite direction when it is off? If so, free75degree's pencil drawing could be simplified further by having one pump on the top line from the tank and one on the bottom line of the tank pointing in opposite directions. So long as they were on a relay and couldn't run at the same time and so long as water can reverse through the pump without causing damage woud it work? Just a thought.

Yes, you can, but you are going to have a very high pressure drop through the nonoperating pump; probably enough to force you to go to a bigger pump. There are better ways...

Chris

Jersey Bill

Member

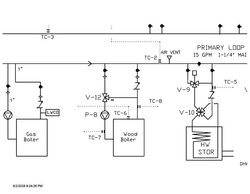

Most folks seem to prefer the system that they have, and I am no exception. I always use the primary-secondary setup. with this, the piping arrangement is straight forward. Attached is a diagram of a job that I am working on. I posted an image of this particular tank going in.

The tank is a concrete septic tank, about 1200 gallons. We plan on using 2 - 3/4"x 200ft coils in parallel for the boiler system, plus 1 coil for DHW preheat (not shown). This is similar to the STSS setup.

When the thermal storage is in use, V-9 will divert all the primary water through the coils. V-10 will change the flow direction thru the coils depending whether charging or discharging the TS. According to STSS, these 2 coils should be good for up to 150 MBH. The pri-sec setup totally separates the loads from the supplies.

To use a heatx in this system, the pump and heatx would be placed ahead of the 4-way valve v-10. You would still need to reverse the flow direction to maintain stratification.

I studied both methods and settled on this one for the following reasons: the valves (v9,10) have a very low pressure drop, the valves will last longer than a pump, the valves use less power. Also, i think that the water inside the tank will get a little icky, potentially fouling a pump and heatx. I just feel more comfortable leaving the storage water alone and not messing with it.

When I looked at the flow rates and pressure drop through the heatx, I didnt think that an 007 would do it. If we go with a 10 deg delta, to get 100 MBH, a flow rate of 20 GPM is required. When I looked at heatx pressure drops, I found around 10 ft of head was common, the 007 wont do it. At 9 ft of head, the 007 is only good for 5GPM. Also, since its an open tank a bronze pump is needed, an iron one would rust away. Another issue that I can think of is that it might be hard to suck 20 gpm from the surface of the tank. there is a term called NPSH, net positive suction head. with a suction inlet near the top, its going to want to suck air. I dont know how deep you might have to go to avoid this, but going deeper is counter productive to the stratification.

The tank is a concrete septic tank, about 1200 gallons. We plan on using 2 - 3/4"x 200ft coils in parallel for the boiler system, plus 1 coil for DHW preheat (not shown). This is similar to the STSS setup.

When the thermal storage is in use, V-9 will divert all the primary water through the coils. V-10 will change the flow direction thru the coils depending whether charging or discharging the TS. According to STSS, these 2 coils should be good for up to 150 MBH. The pri-sec setup totally separates the loads from the supplies.

To use a heatx in this system, the pump and heatx would be placed ahead of the 4-way valve v-10. You would still need to reverse the flow direction to maintain stratification.

I studied both methods and settled on this one for the following reasons: the valves (v9,10) have a very low pressure drop, the valves will last longer than a pump, the valves use less power. Also, i think that the water inside the tank will get a little icky, potentially fouling a pump and heatx. I just feel more comfortable leaving the storage water alone and not messing with it.

When I looked at the flow rates and pressure drop through the heatx, I didnt think that an 007 would do it. If we go with a 10 deg delta, to get 100 MBH, a flow rate of 20 GPM is required. When I looked at heatx pressure drops, I found around 10 ft of head was common, the 007 wont do it. At 9 ft of head, the 007 is only good for 5GPM. Also, since its an open tank a bronze pump is needed, an iron one would rust away. Another issue that I can think of is that it might be hard to suck 20 gpm from the surface of the tank. there is a term called NPSH, net positive suction head. with a suction inlet near the top, its going to want to suck air. I dont know how deep you might have to go to avoid this, but going deeper is counter productive to the stratification.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 5

- Views

- 2K

- Replies

- 12

- Views

- 3K