My piping requirements seem rather simple, perhaps I am too naive. High temperature for the house which is the largest volume (max 10gpm if Wirsbo is correct 65gpm), low temperature requirements for the shop which is in-floor heat only (max 35gpm). I do not anticipate any further buildings or loads.

Is it necessary to use Primary and secondary piping for these needs using the Garn?

Please advise me in the right direction, I have been reading the archives so much that I feel you are all my neighbors! It is time I make some decisions. I picked up my black pipe Monday and finished insulating my overhang ceiling last night. I will start on the OSB today.

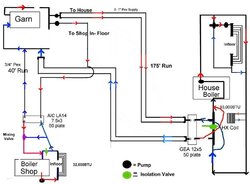

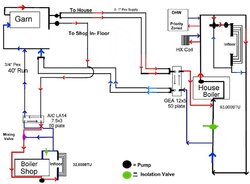

I have attached a sketch of roughly how I plan to plumb the system using Isolation valves to utilize the existing pumps. This diagram does not show all valves, strainers, unions, relays, etc. I do realize I may be better off isolating the boilers but I am not that far in the planning stage today to address that topic. My main concern is piping the lines in the Garn barn at this time.

Thanks for the help, George

Is it necessary to use Primary and secondary piping for these needs using the Garn?

Please advise me in the right direction, I have been reading the archives so much that I feel you are all my neighbors! It is time I make some decisions. I picked up my black pipe Monday and finished insulating my overhang ceiling last night. I will start on the OSB today.

I have attached a sketch of roughly how I plan to plumb the system using Isolation valves to utilize the existing pumps. This diagram does not show all valves, strainers, unions, relays, etc. I do realize I may be better off isolating the boilers but I am not that far in the planning stage today to address that topic. My main concern is piping the lines in the Garn barn at this time.

Thanks for the help, George