For anyone who is so inclined, here are directions for modifying a Grundfos UPS15-58FC 3 speed circulator for computerized control. Note: following these directions is at your own risk. It may void your warranty, curdle your milk, and cause spontaneous defenestration. You've been warned.

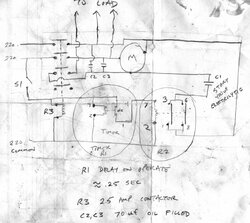

This approach is designed to be 'fail safe': If no power is applied to any of the relays, the pump will be under the control of the EKO controller.

My control system is designed to drive 12vdc relays. Three relays are needed: two DPDT and one SPDT. Almost any will work - I used Potter Brumfield relays from Digi-Key, part number PB968-ND at $1.90. These are rated at 8 amps. At that price, you can use these for the SPDT relay as well.

One relay - the 'Assert' relay - switches control from the EKO to my controller when power is applied. The other two relays replace the function of the speed selector switch on the pump, and add a fourth 'Off' position.

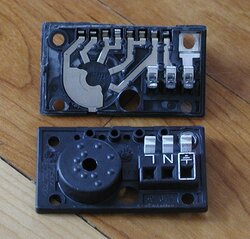

1) Take the cover off and remove the screws holding in the switch / contact assembly. Remove this assembly by pulling it up gently. It is basically an 8 prong plug.

2) Pry / cut the cover off of the switch / contact assembly. Discard the rotating switch component.

..continued...

This approach is designed to be 'fail safe': If no power is applied to any of the relays, the pump will be under the control of the EKO controller.

My control system is designed to drive 12vdc relays. Three relays are needed: two DPDT and one SPDT. Almost any will work - I used Potter Brumfield relays from Digi-Key, part number PB968-ND at $1.90. These are rated at 8 amps. At that price, you can use these for the SPDT relay as well.

One relay - the 'Assert' relay - switches control from the EKO to my controller when power is applied. The other two relays replace the function of the speed selector switch on the pump, and add a fourth 'Off' position.

1) Take the cover off and remove the screws holding in the switch / contact assembly. Remove this assembly by pulling it up gently. It is basically an 8 prong plug.

2) Pry / cut the cover off of the switch / contact assembly. Discard the rotating switch component.

..continued...