Poor man's variable speed pump

- Thread starter Nofossil

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

raybonz

Minister of Fire

Eric Johnson said:"Relative" moron in technical matters. My talents lie elsewhere.

I'm in awe of you guys.

Eric we all have our talents and you certainly have yours!! I will be picking your brain I guarantee it!!

rAY

Eric Johnson said:Not to hijack the hijack, but I'd like a layman's description of what you've done with that Grundfos pump, nofossil.

Would it be fair to say that you've replaced a three-speed switch with circuitry that allows an infinite number of speed settings, made by a computer, within the speed range of that pump?

And if so, how is the speed regulated? Would it be analogous to a computer-controlled dimmer switch?

What happens to your boiler if your computer network goes down? Does it default to the boiler's controller?

Ray has it exactly right - my relays replace the manual switch. It's still a three speed pump, but now it can be controlled by the computer in response to inlet and outlet temps.

It does in fact default to the boiler's controller if my controller goes down. In that case, it runs at high speed when the EKO applies power. That's what I mean by 'failsafe'. I've been pretty careful to design everything that way. If my computer went down, everything except storage would continue to work fine - just like it came from the factory, so to speak.

Part of my makeup is that I'm really cheap. This pump with mods is cheaper than the industrial SCR speed control that Jersey Bill was kind enough to reference. I'll be buying one of those for my fan, where I need a lot more control than just three speeds, but I'm more happy with this cheap pump solution. I get a lot of satisfaction in figuring out inexpensive but technically sound solutions to this kind of problem.

To be even more specific, my controller will work fine without the network - all I'll lose is datalogging. Coming from an aerospace background, I'm a little obsessive about thinking of failures and how to minimize the effects.

raybonz

Minister of Fire

nofossil said:Eric Johnson said:Not to hijack the hijack, but I'd like a layman's description of what you've done with that Grundfos pump, nofossil.

Would it be fair to say that you've replaced a three-speed switch with circuitry that allows an infinite number of speed settings, made by a computer, within the speed range of that pump?

And if so, how is the speed regulated? Would it be analogous to a computer-controlled dimmer switch?

What happens to your boiler if your computer network goes down? Does it default to the boiler's controller?

Ray has it exactly right - my relays replace the manual switch. It's still a three speed pump, but now it can be controlled by the computer in response to inlet and outlet temps.

It does in fact default to the boiler's controller if my controller goes down. In that case, it runs at high speed when the EKO applies power. That's what I mean by 'failsafe'. I've been pretty careful to design everything that way. If my computer went down, everything except storage would continue to work fine - just like it came from the factory, so to speak.

Part of my makeup is that I'm really cheap. This pump with mods is cheaper than the industrial SCR speed control that Jersey Bill was kind enough to reference. I'll be buying one of those for my fan, where I need a lot more control than just three speeds, but I'm more happy with this cheap pump solution. I get a lot of satisfaction in figuring out inexpensive but technically sound solutions to this kind of problem.

To be even more specific, my controller will work fine without the network - all I'll lose is datalogging. Coming from an aerospace background, I'm a little obsessive about thinking of failures and how to minimize the effects.

I'm sure 3 preset speeds will suffice with circulator operation...

Ray

steam man

Minister of Fire

I came across this site while researching variable drive stuff for my own project. Looks interesting but I have never seen any of it used. Probably more of a rich man's thing. I'm cheap too-or so they say.

http://www.controlres.com/ac.htm

http://www.controlres.com/ac.htm

steam man said:I came across this site while researching variable drive stuff for my own project. Looks interesting but I have never seen any of it used. Probably more of a rich man's thing. I'm cheap too-or so they say.

http://www.controlres.com/ac.htm

Looks really cool, but no prices or purchasing info. If you have to ask, you can't afford it.

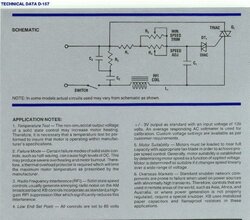

Could something like this be utilized to control a pump? My idea was to replace the pot with a thermistor/resistor network to control pump speed. I've tried to attach photos of the pertinent pages of the manual. If they aren't readable I also attached the link. These are $5 on ebay, by the way. I bought some for R&D;. If anyone has any ideas let me know and I'll butcher some of these up.

http://www.kbelectronics.com/catalog_fan_dist_panel.htm

http://www.kbelectronics.com/catalog_fan_dist_panel.htm

Attachments

termite said:Could something like this be utilized to control a pump? My idea was to replace the pot with a thermistor/resistor network to control pump speed. I've tried to attach photos of the pertinent pages of the manual. If they aren't readable I also attached the link. These are $5 on ebay, by the way. I bought some for R&D;. If anyone has any ideas let me know and I'll butcher some of these up.

http://www.kbelectronics.com/catalog_fan_dist_panel.htm

I think these would work for manual speed control. The Taco is a PSC (permanent split capacitor) motor, ifI remember correctly.

The problem with these is that I don't have enough circuit design experience to figure out how to adapt them to computer based control. If anyone wants to chime in, I'll try it.

wdc1160

New Member

Solid state switching is ideally suited towards applications in the HVAC world.

I am not certain the model your espousing for your system. But, it is going to depend on your circ.

I am also hazy on how you propose your going to use this in conjunction with thermisors. But, you definately are hitting on a technology that runs parallel or over what we deem as the "poor mans variable speed pump"

I am not certain the model your espousing for your system. But, it is going to depend on your circ.

I am also hazy on how you propose your going to use this in conjunction with thermisors. But, you definately are hitting on a technology that runs parallel or over what we deem as the "poor mans variable speed pump"

ABGWD4U said:Solid state switching is ideally suited towards applications in the HVAC world.

I am not certain the model your espousing for your system. But, it is going to depend on your circ.

I am also hazy on how you propose your going to use this in conjunction with thermisors. But, you definately are hitting on a technology that runs parallel or over what we deem as the "poor mans variable speed pump"

I suspect that termite was thinking about replacing the pot in the KB controller with a thermistor and resistor so that the pump speed would vary with temperature. That probably would work within a range of temperatures. Thermistors are wildly non-linear and you have to limit current to prevent self heating, but it's an interesting idea.

What I want is the same circuit, but with an electrically isolated 0-5V analog input so I can control it directly with my computer.

The Crydom controller mentioned earlier is very close to what I want. It handles a lot more current than I need, the input voltages don't quite match my outputs, and it costs more than the pump. I'll still probably get one unless I can figure a way to use this cute little KB unit.

If anyone can suggest a way to modify the KB to fit my needs, I'll test it and post a writeup on the mods.

raybonz

Minister of Fire

nofossil said:termite said:Could something like this be utilized to control a pump? My idea was to replace the pot with a thermistor/resistor network to control pump speed. I've tried to attach photos of the pertinent pages of the manual. If they aren't readable I also attached the link. These are $5 on ebay, by the way. I bought some for R&D;. If anyone has any ideas let me know and I'll butcher some of these up.

http://www.kbelectronics.com/catalog_fan_dist_panel.htm

I think these would work for manual speed control. The Taco is a PSC (permanent split capacitor) motor, ifI remember correctly.

The problem with these is that I don't have enough circuit design experience to figure out how to adapt them to computer based control. If anyone wants to chime in, I'll try it.

You are correct that the Taco 007 is a PSC motor so no speed control can be used on that model pump.. Check out this bad boy they make: http://www.taco-hvac.com/en/product...Circulator/products.html?current_category=194

Ray

Sorry I messed up you CAN use speed control with this motor.. Think I'm going brain dead..

Ray

raybonz

Minister of Fire

nofossil said:ABGWD4U said:Solid state switching is ideally suited towards applications in the HVAC world.

I am not certain the model your espousing for your system. But, it is going to depend on your circ.

I am also hazy on how you propose your going to use this in conjunction with thermisors. But, you definately are hitting on a technology that runs parallel or over what we deem as the "poor mans variable speed pump"

I suspect that termite was thinking about replacing the pot in the KB controller with a thermistor and resistor so that the pump speed would vary with temperature. That probably would work within a range of temperatures. Thermistors are wildly non-linear and you have to limit current to prevent self heating, but it's an interesting idea.

What I want is the same circuit, but with an electrically isolated 0-5V analog input so I can control it directly with my computer.

The Crydom controller mentioned earlier is very close to what I want. It handles a lot more current than I need, the input voltages don't quite match my outputs, and it costs more than the pump. I'll still probably get one unless I can figure a way to use this cute little KB unit.

If anyone can suggest a way to modify the KB to fit my needs, I'll test it and post a writeup on the mods.

This may interest you.. check out the spec sheet..

http://web4.automationdirect.com/adc/Shopping/Catalog/Process_Controls/Signal_Conditioners/FC-33

Ray

raybonz said:I think these would work for manual speed control. The Taco is a PSC (permanent split capacitor) ....

They work manually. I've played around with that. The current draw goes up a little when you slow the pump way down. I'm not sure if the speed control unit is soaking that up (the triac heat sink does get warm) or if the pump motor does.

Nofossil: If you want one to play with I'll mail you one.

raybonz

Minister of Fire

termite said:raybonz said:I think these would work for manual speed control. The Taco is a PSC (permanent split capacitor) ....

They work manually. I've played around with that. The current draw goes up a little when you slow the pump way down. I'm not sure if the speed control unit is soaking that up (the triac heat sink does get warm) or if the pump motor does.

Nofossil: If you want one to play with I'll mail you one.

5 dollars was a real bargain on those speed controls! Were they brand new? You can buy heat sinks for those to protect the speed control from heat failure, if you do add heat sink compound to enhance heat transfer to the heat sink from the control..

Ray

raybonz said:You are correct that the Taco 007 is a PSC motor so no speed control can be used on that model pump.. Check out this bad boy they make: http://www.taco-hvac.com/en/product...Circulator/products.html?current_category=194

Ray

Sorry I messed up you CAN use speed control with this motor.. Think I'm going brain dead..

Ray

I looked at Taco's variable speed pump. It was around $600 three years ago. That's more than all three circulators in my system PLUS the 7260 controller, A/D boards, additional digital I/O board, relays, and wiring.

sled_mack

New Member

Nofossil,

There are two ways for you to replace the speed pot on that drive.

First is to use a high speed PWM output from your computer. I'd say 5kHz is the min freq that will run smoothly. Most high speed outputs are low voltage/current, so you may need a high speed isolating relay (must be solid state, not dry contacts) between your output and the drive. That works very well, becuase the computer output is isolated from the drive voltage. The high speed relay is probably going to run about $50.

The second way is to use an analog isolator. These are common in process control industry when an instrument has it's own power source and needs to be isolated from the computer input. But, they are generally a bit pricey. It would work like a champ, taking your analog output (0-10 V, 4-20mA, 0-5V, etc) and converting to the drive's voltage of 0-5V.

Generally speaking motors not designed for variable speed use will get quite hot if run less then 60% of rated full speed. I don't know if that applies here or not, as I don't know enough about these motors. But, I would set the min speed on the drive to something like 60%, then use the analog signal to control between that and full speed. Use a separate relay to stop the drive completely.

There are two ways for you to replace the speed pot on that drive.

First is to use a high speed PWM output from your computer. I'd say 5kHz is the min freq that will run smoothly. Most high speed outputs are low voltage/current, so you may need a high speed isolating relay (must be solid state, not dry contacts) between your output and the drive. That works very well, becuase the computer output is isolated from the drive voltage. The high speed relay is probably going to run about $50.

The second way is to use an analog isolator. These are common in process control industry when an instrument has it's own power source and needs to be isolated from the computer input. But, they are generally a bit pricey. It would work like a champ, taking your analog output (0-10 V, 4-20mA, 0-5V, etc) and converting to the drive's voltage of 0-5V.

Generally speaking motors not designed for variable speed use will get quite hot if run less then 60% of rated full speed. I don't know if that applies here or not, as I don't know enough about these motors. But, I would set the min speed on the drive to something like 60%, then use the analog signal to control between that and full speed. Use a separate relay to stop the drive completely.

raybonz

Minister of Fire

nofossil said:raybonz said:You are correct that the Taco 007 is a PSC motor so no speed control can be used on that model pump.. Check out this bad boy they make: http://www.taco-hvac.com/en/product...Circulator/products.html?current_category=194

Ray

Sorry I messed up you CAN use speed control with this motor.. Think I'm going brain dead..

Ray

I looked at Taco's variable speed pump. It was around $600 three years ago. That's more than all three circulators in my system PLUS the 7260 controller, A/D boards, additional digital I/O board, relays, and wiring.

Yikes that's an expensive lil devil eh? I could practically replace my oil fired boiler for that much! External speed control is definitely the way to go..

Ray

wdc1160

New Member

nofossil said:ABGWD4U said:Solid state switching is ideally suited towards applications in the HVAC world.

I am not certain the model your espousing for your system. But, it is going to depend on your circ.

I am also hazy on how you propose your going to use this in conjunction with thermisors. But, you definately are hitting on a technology that runs parallel or over what we deem as the "poor mans variable speed pump"

I suspect that termite was thinking about replacing the pot in the KB controller with a thermistor and resistor so that the pump speed would vary with temperature. That probably would work within a range of temperatures. Thermistors are wildly non-linear and you have to limit current to prevent self heating, but it's an interesting idea.

What I want is the same circuit, but with an electrically isolated 0-5V analog input so I can control it directly with my computer.

The Crydom controller mentioned earlier is very close to what I want. It handles a lot more current than I need, the input voltages don't quite match my outputs, and it costs more than the pump. I'll still probably get one unless I can figure a way to use this cute little KB unit.

If anyone can suggest a way to modify the KB to fit my needs, I'll test it and post a writeup on the mods.

I should have seen that- thanks nofo.

Some of these approaches seem like they are very doable.

I am a fan of having the computer make the final say so(and logging) I have never used a sensor to directly control anything, but having some controls distributed could be a good thing.

I am not at this stage of development with the control, but I have in the past used Omron brand solid state switches aka "solid state relays"

by design they made to order when if comes to controling capacitive and inductive loads.

Depending on the input V and output V you can getem for as little as $3 and unless you have to control obscene loads no more than $15

I think most importantly they are made for applications such as these. Some of the other electronics listed here may not have been(I haven't checked). Consequently, you'll find that these will last as long as your boiler.

This is something we defineiatly need to explore more to find the pros and cons of certain equipment, to the pros and cons of distributing the control of these pumps, solenoids and sensors.

Keep up the good work guys.

On my timeline is March 15, I will be doing the tests involving the Omron 3m line of SIP switches. Hopefully it will be help for next season.

raybonz said:5 dollars was a real bargain on those speed controls! Were they brand new?

Ray

Yep, brand new. Search for "Solid State AC speed Control for Blower motors" in Ebay. I paid $4.95@ for mine. He has jacked the price up to $5.95. He had a bunch of them when I got mine. He has three up right now. They are the KBMC-13's.

raybonz

Minister of Fire

termite said:raybonz said:5 dollars was a real bargain on those speed controls! Were they brand new?

Ray

Yep, brand new. Search for "Solid State AC speed Control for Blower motors" in Ebay. I paid $4.95@ for mine. He has jacked the price up to $5.95. He had a bunch of them when I got mine. He has three up right now. They are the KBMC-13's.

At KB's site they sell them for $19.00 so you indeed got a bargain.. As long as you can desolder the speed pot you should be able to use external speed control once you determine what voltage they're using at the pot you may be able to use 0-5v or 0-10v or even 0-2.5vdc reference all of those being common. It's too bad that KB doesn't make one of those with external reference as an option.. I have used KB DC drives and they work pretty well and are very compact.. Will be interesting seeing who figures it 1st.. My money is on Nofossil..

Ray

raybonz

Minister of Fire

termite said:Could something like this be utilized to control a pump? My idea was to replace the pot with a thermistor/resistor network to control pump speed. I've tried to attach photos of the pertinent pages of the manual. If they aren't readable I also attached the link. These are $5 on ebay, by the way. I bought some for R&D;. If anyone has any ideas let me know and I'll butcher some of these up.

Termite,

Have you considered R1 as your point for speed control? Once you know the value you could replace R1 with an external resistance if it is standard such as 1k, 5k, 10k, etc. . Being 2 wire it would be simpler to do.. Just a thought..

Ray

http://www.kbelectronics.com/catalog_fan_dist_panel.htm

No I haven't, but that's a good idea. That would be a lot simpler mod. The functionality of the speed pot would be preserved as well to help fine tune for the application.raybonz said:Termite,

Have you considered R1 as your point for speed control?

Sled_mack mentioned not letting the speed drop below 60%. The R2 pot would be the place to make that adjustment.

raybonz

Minister of Fire

Looking at the schematic I am wondering what voltage your dealing with. Looks like it will be AC not DC so you gotta be sure that your control device is rated to handle the voltage.. You sure have me thinking!termite said:No I haven't, but that's a good idea. That would be a lot simpler mod. The functionality of the speed pot would be preserved as well to help fine tune for the application.raybonz said:Termite,

Have you considered R1 as your point for speed control?

Sled_mack mentioned not letting the speed drop below 60%. The R2 pot would be the place to make that adjustment.

Ray

raybonz said:As long as you can desolder the speed pot you should be able to use external speed control once you determine what voltage they're using at the pot you may be able to use 0-5v or 0-10v or even 0-2.5vdc reference all of those being common. It's too bad that KB doesn't make one of those with external reference as an option.. I have used KB DC drives and they work pretty well and are very compact.. Will be interesting seeing who figures it 1st.. My money is on Nofossil..

Ray

Nofossil is a mechanical engineer, unfortunately. Looking at the schematic, I see three problems:

1) The voltage coming off the pots is AC

2) That voltage is referenced to the 110vac ground - toxic for delicate analog outputs

3) I can't really read schematics

I'm hoping an electrical engineer will look at this and post a simple solution - "You just need to desolder the pot and stick in an AD-97532 optically isolated fribblespatzer."

BrownianHeatingTech

Minister of Fire

nofossil said:I'm hoping an electrical engineer will look at this and post a simple solution - "You just need to desolder the pot and stick in an AD-97532 optically isolated fribblespatzer."

If you do that, you'll need to remove the standard capacitor from the PSC motor and replace it with a flux capacitor. Make sure it's a 5 microfarad unit, though - the 10 microfarad flux capacitors will send your circulator back to the 1950's...

Joe

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 7K