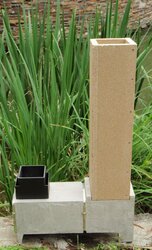

The 6" castle build in the picture needs to be fed every 40 mins or so. Fuel is should be 1.5"-2.5" split. Length of 2 ft works fine, if you had a ring taller to make sure wood stays upright you could go longer. Only the tips of the wood burn and as it is burned, the wood self feeds. Of course unless you are using lumber scraps, wood is often split unevenly, so i find it best to put the thickest end in the fire first so that as it burns down, it does not "hang". If feeding just a few pieces at a time I put the fresh pieces towards the fire and push the lit pieces towards the back. This keeps the older burning piece upright and fuels the burning of the new cold pieces.

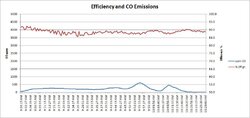

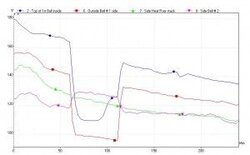

Generally you would run the stove for 3-4 hours and then it will give off heat for the next eight. The longer you fire it the more heat it stores. So a 12 hour cycle would be 3-4 hours of burning and 8 hours of release. The dip was from stirring coals. After 6 hours the inside of the 1st bell was still around 135 F, the outside 120 F. It take about an hour per 1.5" of material for the heat to show up. So if you have the 2 inside layers and then skin the stove, it may take a couple hours for the heat to really show up strongly. But like masonry heaters it will keep coming for hours.

Here is link to a blog that show a heat loss data log for 6 hours.

View attachment 120951

http://blog.dragonheaters.com/category/flue-build-part-4/

The 6" can only burn about 4-5 lbs of wood an hour. The 8" 12 lbs. The radiated BTUs will be 10-15K for the 6" and 20-25k for the 8". Basically for your heat load you would need either 2 6"s or an 8".

Hope this helps.