webbie

Seasoned Moderator

MountainStoveGuy said:Im one who is typically on cautious side, i think people here get that. The altitude plays havoic with draft, and our inspectors over regulate. Its not a installation i push, but i dont know if its illeagle. If a insert can fit in the box, then why cant a stove be outside the box? I would think the stove outside the box would be a safer install then a insert. Doesnt seem logical to me. If you back up a stove, to the point that the flue collar is inside the firebox, i dont see any pipe combustable issues there, but i do see issues with the stove being to close to combustable framing of the ZC fireplace. So lets say you pull the stove out and treat the ZC like a combustable, and run double wall back to a T and up? It would seem that would be ok. I will agree with you craig, on your .02. And i would like to add, that not one hearthstone appliance manual states that in can be installed in a ZC firebox. I think i will call them.

MSG, I'm fairly certain here that your suggestions are against the listings.

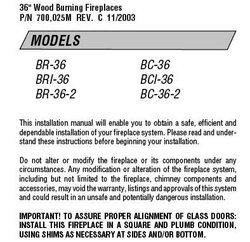

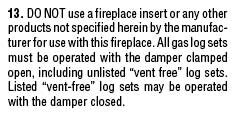

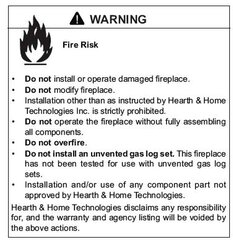

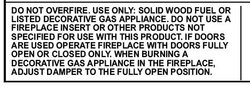

Enclosed, for example, are three tidbits from the Lennox manual.

Notice the warnings.....

1. Do not modify

2. Do not install inserts (a LISTED insert FOR THIS FIREPLACE may superceed this)

3. A pic showing the framing.

As to your idea of a stove being backed up against it, given the framing that you see in the picture, how could the stove possible meet clearances? There is wood within a few inches right behind the sheetrock.

I agree that perhaps your idea of the stove pulled all the way into the room (with proper hearth) and then a complete class A chimney system might be OK...then again, it would not fit within a 8" and it would not have air around it. Bottom line - no one would do this - the fireplace should be ripped out along with the chimney - and then the generic class A installed.

I am fairly certain on all this, as the manual also seems to indicate. Scary that inspectors allow this.....

You can call HearthStone, but the real party involved is the pre-fab maker. I'm fairly certain the right person at each will say the same thing.