After hearing about how well a block off plate has worked for some people to retain heat, and the poor heat output I am getting out of my Rockland despite its reputation, well I think I need one.

I've read over the article and have a few questions still. One thing, I have lots of silicone like GE I clear, will that really be ok to use in such proximity? My plate would only be a couple inches from the stovetop, and my Rockland routinely sees 700-750 when I load it fully. Seems awfully hot for silicone but I guess I dont really know how hot silicone can take.

Another thing, the article mentions using furnace cement around the pipe. If it were cemented in place how does it 'give' for installation and removal? I didnt install the unit myself, but would the pipe not have to move up a couple inches to unhook it from the collar?

The article mentions nothing about insulation, yet many say to add insulation to the top of the plate. Is insulation helpful? Does it need to be a specific kind? I believe its double wall pipe were it will pass through the block off plate but not 100% sure until I pull it and look (tomorrow).

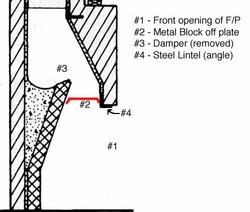

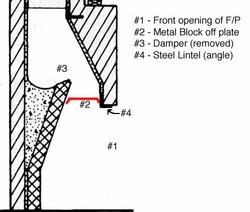

Lastly, the article shows a piece of angle iron but says nothing of it. Is it necessary? Can it be installed with just silicone? #4 in the photo:

I plan on letting the stove die out in the morn and taking the day to clean the chimney for the first time and inspect everything. Will pull the insert and hopefully install the block off plate. It suppose to warm up the next few days so that should give everything time to dry (meaning I wont need to burn the insert).

Thanks for any help!

I've read over the article and have a few questions still. One thing, I have lots of silicone like GE I clear, will that really be ok to use in such proximity? My plate would only be a couple inches from the stovetop, and my Rockland routinely sees 700-750 when I load it fully. Seems awfully hot for silicone but I guess I dont really know how hot silicone can take.

Another thing, the article mentions using furnace cement around the pipe. If it were cemented in place how does it 'give' for installation and removal? I didnt install the unit myself, but would the pipe not have to move up a couple inches to unhook it from the collar?

The article mentions nothing about insulation, yet many say to add insulation to the top of the plate. Is insulation helpful? Does it need to be a specific kind? I believe its double wall pipe were it will pass through the block off plate but not 100% sure until I pull it and look (tomorrow).

Lastly, the article shows a piece of angle iron but says nothing of it. Is it necessary? Can it be installed with just silicone? #4 in the photo:

I plan on letting the stove die out in the morn and taking the day to clean the chimney for the first time and inspect everything. Will pull the insert and hopefully install the block off plate. It suppose to warm up the next few days so that should give everything time to dry (meaning I wont need to burn the insert).

Thanks for any help!

Last edited by a moderator: