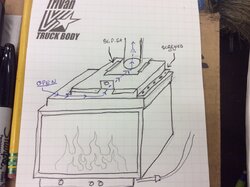

Trying to help a friend here. He was recently "re-issued" his house post-divorce. While he was away, the existing gas fireplace died, so his ex and a friend bought a used one, and attempted to install it. The story I got was of a 12' ball of fire into the living room. I went to investigate. I found no leaks with my testing, so very carefully, I lit the pilot. All was well, but the burner would not light. I got it to light with a lighter, although a little sluggishly. I reached under to adjust the valve and WHOOOSH! No more arm hair and a 12' ball of flame. We shut down and began to investigate further, and still could not find a leak. I test lit it again, even more carefully this time. Ultimately, it gave me a similiar result, although expecting it, I was able to keep what hair I had left. Time to throw in the towel. We removed the fireplace and brought it to the shop. I have disassembled it and began testing it further with air instead of gas. (Figured it was a bit safer). I still cannot find a leak, but did learn something. If the pressure is above 3-31/2psi, it will bleed off through the pilot circuit, ONCE THE PILOT KNOB IS PUSHED IN AS IF LIGHTING. once it drops of to 3psi or so, it will seal up.

The valve assembly appears to be - SIT 820 NOVA mV. The sticker reads "For Natural Gas Only". However, the flame adjustment valve attached to it reads- "For LPG only. Pout 10 "W.C. Temp range 32f to 225f

How can I know if this is setup for propane? With the symptoms, I am doubting it. With propane being heavier than air, and the valve sticking open at higher pressure, it stands to reason that the gas would build under the firebox, and cause me that big poof. Is this how a nat gas unit might act if connected to propane?

That pilot light sort of seems to be acting like a pop off valve you'd find on an air compressor tank. I can sort of pull against the spring and help it seal before it gets down to 3psi, but it won't hold on it's own.

Any help is greatly appreciated!

The valve assembly appears to be - SIT 820 NOVA mV. The sticker reads "For Natural Gas Only". However, the flame adjustment valve attached to it reads- "For LPG only. Pout 10 "W.C. Temp range 32f to 225f

How can I know if this is setup for propane? With the symptoms, I am doubting it. With propane being heavier than air, and the valve sticking open at higher pressure, it stands to reason that the gas would build under the firebox, and cause me that big poof. Is this how a nat gas unit might act if connected to propane?

That pilot light sort of seems to be acting like a pop off valve you'd find on an air compressor tank. I can sort of pull against the spring and help it seal before it gets down to 3psi, but it won't hold on it's own.

Any help is greatly appreciated!