This stove just sold on ebay, I have the exact stove, only my stove although the same year has only been used for like 4 seasons, the pictures are here though in this link

http://cgi.ebay.com/ws/eBayISAPI.dl...30171762_W0QQfromZR40QQfviZ1#ebayphotohosting

My stove looks brand new compared to this,

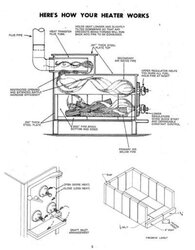

Question- I used this all last season, but never really learned the sweet spot or how , with the sake of seeming dumb, to really use the intake knobs 4 of them, i usually open em up all the way , then only close half way, I think i could do better, also check out my damper. or flue in the picture showing the back of stove it opens up completly across back of stove, can this be partly closed while burning?

Elk- this is the picture of the damper we discussed last year to try to make a connection for a direct connect of some sort, opens up to like 3 inches X 29 wide, I pull her once a month to check for creosote etc while i do the chimney, never got that bad, but i confess i never did an overnight burn with her

any seasoned burners out there that can give me tips to get the right burn, I have been doing small hot fires to avoid the creeosote, due to venting into masonary flue 7x 12 inner diameter

http://cgi.ebay.com/ws/eBayISAPI.dl...30171762_W0QQfromZR40QQfviZ1#ebayphotohosting

My stove looks brand new compared to this,

Question- I used this all last season, but never really learned the sweet spot or how , with the sake of seeming dumb, to really use the intake knobs 4 of them, i usually open em up all the way , then only close half way, I think i could do better, also check out my damper. or flue in the picture showing the back of stove it opens up completly across back of stove, can this be partly closed while burning?

Elk- this is the picture of the damper we discussed last year to try to make a connection for a direct connect of some sort, opens up to like 3 inches X 29 wide, I pull her once a month to check for creosote etc while i do the chimney, never got that bad, but i confess i never did an overnight burn with her

any seasoned burners out there that can give me tips to get the right burn, I have been doing small hot fires to avoid the creeosote, due to venting into masonary flue 7x 12 inner diameter