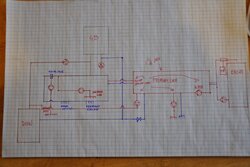

Hi folks, I have redrawn my piping for my Eko 40. I have been looking over master of Sparks sticky and tried to get it as close to his primary secondary diagram as I could.

Of course I have a few questions.

1) will it work

2) will the alpa circ pump work as boiler protection.

3) I am not sure about sizing the alpha pump , Is there only one size ?

I will also be plumbing in extra close spaced tees for storage and a oveheat loop for later use.

the primary loop would be close to 100' of 1-1/4 pex except the piping close to the boiler which will be black iron.

I will be shutting off the GB while running the EKO 40. All the load pumps will be powered except the GB boiler pump and dhw pump.

thanx huff

Of course I have a few questions.

1) will it work

2) will the alpa circ pump work as boiler protection.

3) I am not sure about sizing the alpha pump , Is there only one size ?

I will also be plumbing in extra close spaced tees for storage and a oveheat loop for later use.

the primary loop would be close to 100' of 1-1/4 pex except the piping close to the boiler which will be black iron.

I will be shutting off the GB while running the EKO 40. All the load pumps will be powered except the GB boiler pump and dhw pump.

thanx huff