My stove only burns on well on low when I have a little caked ash in the bottom of the burn pot. This usually appears after shut down but not always the case.

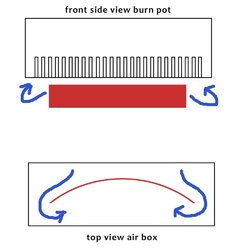

Would it be dangerous if I put something in my burnpot to block the air flow through the middle? I think normally I have too much air going through it with no way to adjust it. I was thinking a metal square would do or even a thin square brick??

My burn pot has slats for the air to go through so plenty of air would still get through. I would maybe be blocking a quarter to a third of the total pot.

Would it be dangerous if I put something in my burnpot to block the air flow through the middle? I think normally I have too much air going through it with no way to adjust it. I was thinking a metal square would do or even a thin square brick??

My burn pot has slats for the air to go through so plenty of air would still get through. I would maybe be blocking a quarter to a third of the total pot.