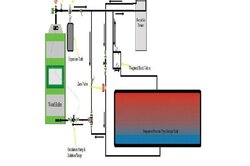

Can you guys tell me what the purpose of the zone valve is in this piping diagram? I assume it is only there to prevent flow through the heat zone when the boiler is running and heat is not needed in the zone, correct? If this is the case couldn't the same thing be accomplished with a flow check valve (for a lot less money)?

One other question: if the boiler is not running, storage is hot, and you have a call for heat from the heat zone what prevents flow through the boiler when the heat zone circ us running? If that were the shorter, less retrictive route would you not get most of your flow from the boiler (cold) and not storage? So do you need two zone valves/flow check valves?

Any comments would be most helpful...pumps and valves are the last thing on my list to purchase!!

One other question: if the boiler is not running, storage is hot, and you have a call for heat from the heat zone what prevents flow through the boiler when the heat zone circ us running? If that were the shorter, less retrictive route would you not get most of your flow from the boiler (cold) and not storage? So do you need two zone valves/flow check valves?

Any comments would be most helpful...pumps and valves are the last thing on my list to purchase!!