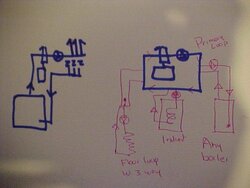

I know this is an old heating concept, a B&G;rep repopularized it in the 60's I hear. I've never heard the whole reasoning. I sat down and drew a little sketch and the lowest pressure in the system always occurs at the pump suction unless I have a a high elevation somewhere else in the system.

I can see the fill point will raise the "base" system pressure if the pressure at its connection point drops below its static fill during operation due to the delta P across the pump.

The best reason I see to pump away from the bladder tank is placing it at the point of lowest pressure in the system (pump inlet) allows it to be slightly smaller and will reduce the "base" system pressure if the fill valve is left on the supply side of the boiler.

Please someone try to explain to me why this old timey tradition stands in small residential systems! I don't see it saving money or helping system functioning.

Why I'm even looking? My water inlet for the boiler is low, and I want to pump up into it so I'll never airlock my pump. The air scoop and float valve need to go on a high area of the system which for me is the boiler outlet leading to the storage tank. My air scoop is made to accept a tank in the bottom of it. I see no reason to try to fanangle the tank below my pump feeding the boiler.

I can see the fill point will raise the "base" system pressure if the pressure at its connection point drops below its static fill during operation due to the delta P across the pump.

The best reason I see to pump away from the bladder tank is placing it at the point of lowest pressure in the system (pump inlet) allows it to be slightly smaller and will reduce the "base" system pressure if the fill valve is left on the supply side of the boiler.

Please someone try to explain to me why this old timey tradition stands in small residential systems! I don't see it saving money or helping system functioning.

Why I'm even looking? My water inlet for the boiler is low, and I want to pump up into it so I'll never airlock my pump. The air scoop and float valve need to go on a high area of the system which for me is the boiler outlet leading to the storage tank. My air scoop is made to accept a tank in the bottom of it. I see no reason to try to fanangle the tank below my pump feeding the boiler.