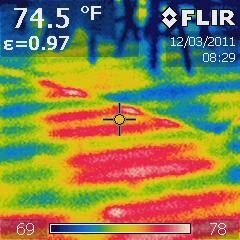

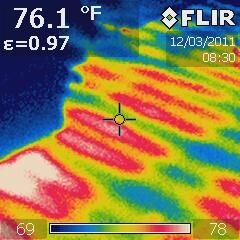

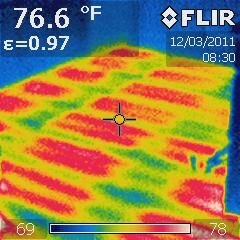

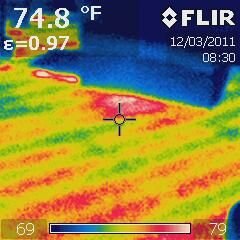

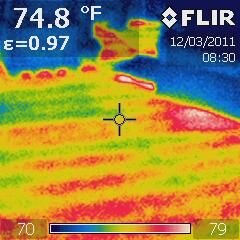

I have radient floor heat...1/2 pex with 2 runs per joist. No runs are longer than 175ft. I noticed in other homes, their floors seem warmer than mine and I have also noticed that from a cold start, it takes hours to bring my home up to temp. Most of my house has a 1" ruff cut subfloor with 1/2" oak hardwood floors. Some areas have tile and others have carpet but the hardwood is 75%. All the pex was hung with nail in pex clamps and then I installed R-11 fiberglass insulation under that (loosly against the pex). I have a mixing valve that reduces the the temp to the pex pipe from 180 to 140-150 (as I was instructed to prevent hardwood floor damage).

Does anyone have an idea why the heat is not transfering as fast as it should or is what I'm seeing normal?

Does anyone have an idea why the heat is not transfering as fast as it should or is what I'm seeing normal?