cycloxer said:

My mother used to put my jeans outside like that, frozen like boards, so I know how much it sucks ;^)

I remember that as well. If you brought in a frozen towel, you could snap it in half if you weren't careful.

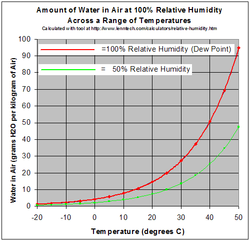

Still, when the stuff thawed out, it was always nearly dry. Mom used to like the coldest nights as she said the clothes actually dried better. Anecdotal evidence for sure, but I never remember putting damp clothes on in the winter, so obviously, some sort of non-vacuum freeze drying occurred. I have always felt that green wood dries much faster after it has been subjected to several deep-freeze cycles (below 0ºF). Anecdotal again, but I've been burning for over 20 years, so there must be at least a little something to my observations.

I always purchase unseasoned wood late in the fall and let it dry through a variety of methods. I ordinarily buy only ash and cherry and pay a premium for it. I just got 2 cords of hickory (another low moisture content wood) which will burn OK for me by February, just when I need the extra heat it will give me the most. Wood supposedly needs at least a full year to fully season, but some woods (like cherry) will initially drop moisture content very rapidly.

All wood dries at a slower rate as seasoning progresses, so after about two months, you start to get a diminishing return for each month spent seasoning. I notice this when I grab a piece of firewood to rough turn a bowl on my lathe. I get soaked from the wood when it is first delivered, but after a few weeks, it doesn't spin out enough water to really wet me. The wood starts to come off in chips rather than in long strings, and they aren't as cool feeling as they hit my hand (a sign of drier wood). They will still check and crack if I don't put them in a bag to dry slowly, but much of the free water has disappeared.

Another thing to understand is case hardening of wood. Woodworkers who use air-dried hardwood are acutely aware of this problem. If you go out in the summer and cut and split a bunch of wood, then stack it in the hottest, driest and windiest conditions summer has to offer, chances are that it will undergo a process whereby the outside of the wood quickly dries to an almost impermeable case around the outside. Eventually, the stresses produced by the differential drying rates will literally pull the wood apart. When that happens, deep cracks will develop and further drying will occur. In time, the wood will reach equilibrium with ambient relative humidity for that time of year, but it may take longer than you think. Most commercial kilns solve this problem by maintaing a very high relative humidity inside the kiln during the initial drying period. That tells me that maybe the best time to cut and stack your wood might be on hot

muggy days instead of the driest ones.

I always ran my old stove as hot as I could get it. Once I started doing that, my chimney sweep stopped yelling about all the creosote. I mix in some really dry wood from the year before - about 20% - when I am going for a long burn (to keep the temps high enough), but when I am awake and around the house I burn the straight semi-seasoned wood. The wood I'm burning right now is cherry that was on the stump less than two months ago. I can easily get the stove temps up to the desired range (and beyond if I'm not careful) with this "green" wood. Little or no sizzling, and even the bigger pieces catch immediately once the stove is running at it's proper level with a good charge of wood. Yeah, I know I lose some heat in evaporation of the remaining moisture, but there's plenty of moisture remaining in wood that has been seasoned even for three years. Among woodworkers, we say "one year per inch thickness" as the time need to air dry wood to the equilibrium MC. How many folks burning those huge splits and rounds we see here have seasoned them for 8-10 years? I'd be curious to know what the MC of a 10" round of three year old red oak is on the inside.

As for me, as long as I'm getting it hot and keeping it up there, I think that's about all I can ask for from my firewood. My new stove settles in at about a 300-350ºF flue pipe temp (600-650ºF stove top temp) with the damper shut regardless of whether I am using straight seasoned or straight semi-seasoned, so I could care less about the extra wood I burn. Maybe an extra face cord or two a year. That's worth not have to move around an extra 5-10 cords of wood every season, or having to have almost 15 cords on my property to get at some three year old stuff.

Burning pellets is easiest, then I imagine those compressed wood bricks are a close second. Burning seasoned wood is a skill. Burning green and semi-seasoned wood is an art. Burning wet red oak takes a miracle.

Just my five cents (hey, I'm feeling generous this morning).

BK