Hi all,

I just purchased a used Jotul Combifire 4, the "Easter Island" wood stove. I am in the process of planning the installation on the first floor/living room, in a new-to-me house. The chimney is single flue, concrete chimney block with a steel liner. Previously, there was only a thimble in the cellar for a big wood furnace, and the chimney is framed out and sheetrocked upstairs. The chimney is centrally located, and adjacent to the far/upper end of the staircase. In other words, there is a framed and sheetrocked corner where the wall below the staircase meets the wall that is framed around the chimney, and wraps around 3 sides of the chimney. Sorry for the lengthy details, but I figure it might be helpful.

What I would like to do is face the above mentioned walls with slate tile, creating a wrap-around hearth for the wood stove, which will go in the corner between stairs and chimney. I spoke with a chimney mason who can install a thimble into my chimney for the woodstove. The current plan is to frame out an opening in the wraparound wall that he can lay brick in to protect the framing from the stovepipe.

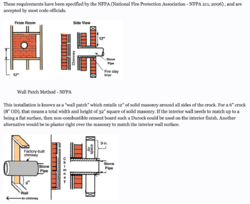

Now, my challenge is to figure out a fire-safe wall assembly on which to install my slate tile hearth on walls and floor, while reducing the clearances dictated by NFPA 211. I would like to place the wood stove in the corner, and I don't have a very large living room so 36" from both walls seems like a lot of space to give up.

Looking online at an insurance company's rules based on the NFPA specs, it seems like the best option for me would be to install the " 1/2" thick noncombustible insulation board with a 1" airspace behind the cement fiber board/thin-set/tile assembly.

Soooo, can anyone tell me what 1/2" noncombustible insulation board is??? I asked my local builders supply, and the didn't know what I was talking about. They recommended Roxul comfortboard, but the minimum thickness is 1.25". I asked if there is another thinner, fireproof sheet good that I could use, but they are unaware of any. I assume that if NFPA specs 1/2", there must be a product out there that is commonly used.

Sorry for the long post. Any thoughts or ideas? Thanks!

-Alex

I just purchased a used Jotul Combifire 4, the "Easter Island" wood stove. I am in the process of planning the installation on the first floor/living room, in a new-to-me house. The chimney is single flue, concrete chimney block with a steel liner. Previously, there was only a thimble in the cellar for a big wood furnace, and the chimney is framed out and sheetrocked upstairs. The chimney is centrally located, and adjacent to the far/upper end of the staircase. In other words, there is a framed and sheetrocked corner where the wall below the staircase meets the wall that is framed around the chimney, and wraps around 3 sides of the chimney. Sorry for the lengthy details, but I figure it might be helpful.

What I would like to do is face the above mentioned walls with slate tile, creating a wrap-around hearth for the wood stove, which will go in the corner between stairs and chimney. I spoke with a chimney mason who can install a thimble into my chimney for the woodstove. The current plan is to frame out an opening in the wraparound wall that he can lay brick in to protect the framing from the stovepipe.

Now, my challenge is to figure out a fire-safe wall assembly on which to install my slate tile hearth on walls and floor, while reducing the clearances dictated by NFPA 211. I would like to place the wood stove in the corner, and I don't have a very large living room so 36" from both walls seems like a lot of space to give up.

Looking online at an insurance company's rules based on the NFPA specs, it seems like the best option for me would be to install the " 1/2" thick noncombustible insulation board with a 1" airspace behind the cement fiber board/thin-set/tile assembly.

Soooo, can anyone tell me what 1/2" noncombustible insulation board is??? I asked my local builders supply, and the didn't know what I was talking about. They recommended Roxul comfortboard, but the minimum thickness is 1.25". I asked if there is another thinner, fireproof sheet good that I could use, but they are unaware of any. I assume that if NFPA specs 1/2", there must be a product out there that is commonly used.

Sorry for the long post. Any thoughts or ideas? Thanks!

-Alex