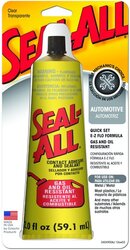

I have a plastic gas tank with a couple crack in the center of a flat spot.

How have you repaired it / can it be repaired?

Is there a tape like duct tape I can use?

How have you repaired it / can it be repaired?

Is there a tape like duct tape I can use?