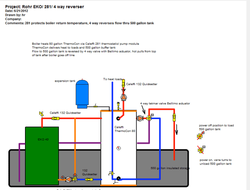

The small 80 gallon tanks acts as a hydro separator and some buffer capacity for the boiler.

It allows heat to go to the loads fairly quickly, then the 500 gallon tank comes on line as the boiler has the capacity to load it.

Ideally you would want to unload the 500 back to the 80 gallon or directly to the load. This dual pump with a 3 way diverting valve allows you to shuffle between the tanks without breaking up the stratifiaction.

That could not be accomplished with just the 4 way reverser in my original plan.

hr

It allows heat to go to the loads fairly quickly, then the 500 gallon tank comes on line as the boiler has the capacity to load it.

Ideally you would want to unload the 500 back to the 80 gallon or directly to the load. This dual pump with a 3 way diverting valve allows you to shuffle between the tanks without breaking up the stratifiaction.

That could not be accomplished with just the 4 way reverser in my original plan.

hr

Until then I would like the boiler to go to the load as quickly as possible, then warm storage for the over load, or nightime use. With radiant slabs I can almost "flywheel" thru the evening hours, so large storage is not a key goal.

Until then I would like the boiler to go to the load as quickly as possible, then warm storage for the over load, or nightime use. With radiant slabs I can almost "flywheel" thru the evening hours, so large storage is not a key goal.