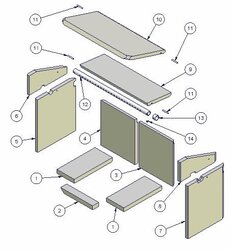

The SCAN 60/61 woodstoves have a hazardous design flaw. I've had my SCAN 60 for about 2 years now

and I've had to replace Skamol pieces (see attachment) #6, #8, and #10 twice. I know there are at least 2 other

SCAN owners that have had the exact same problem. The #6 and #8 triangular side pieces support the weight of the

#10 (damper) piece via small metal pins which plug into holes drilled into #6 & #8. These tend to crack right where the

pins are and in my case, have dropped the top damper twice. Also the dampler (#10) has slots that accept the pins on

each side, which tend to blow out and no longer hold the pins. This is a real safety hazard.

The CPSC is looking into this. I'm wondering if there are any other folks out there that have had the same problem. If so,

the CPSC would probably like to hear from you.

and I've had to replace Skamol pieces (see attachment) #6, #8, and #10 twice. I know there are at least 2 other

SCAN owners that have had the exact same problem. The #6 and #8 triangular side pieces support the weight of the

#10 (damper) piece via small metal pins which plug into holes drilled into #6 & #8. These tend to crack right where the

pins are and in my case, have dropped the top damper twice. Also the dampler (#10) has slots that accept the pins on

each side, which tend to blow out and no longer hold the pins. This is a real safety hazard.

The CPSC is looking into this. I'm wondering if there are any other folks out there that have had the same problem. If so,

the CPSC would probably like to hear from you.