Is it my imagination or have I been seeing pictures of scandinavian boiler/storage systems with storage temps above 100* centigrade? Doesn't that imply system pressures higher than standard here? Is this some more advanced technology that hasn't reached our shores yet?

Scandinavian Storage Temps

- Thread starter DaveBP

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

pybyr

Minister of Fire

if you can do high pressures, you can do temperatures well above the usual boiling point- same principles that allow a pressure cooker to operate and to cook more rapidly than an open simmer or boil. At high pressures, water won't change to steam until well above 212F/ 100C

BUT you'd better have the whole system engineered to deal with the pressures, plus a good margin of headroom for safety, or else you're playing with explosive stuff.

BUT you'd better have the whole system engineered to deal with the pressures, plus a good margin of headroom for safety, or else you're playing with explosive stuff.

I probably ought to learn to use smileys. I was being a little tongue-in-cheek with the "advanced technology" crack. If it's the same boilers coming over here that they are using, the design pressure limits are not different. If the pressure relief valve is set at 30 lbs. over here, is that because of American rules? Do they use pressure relief settings higher over there. The boiling point of water at 15lbs. pressure is about 250F (about 120C ). So the higher temps that I've seen in photos are within the boiling point at our normal 12 lbs. boiler pressure. I was just wondering if they shave the margin of safety in their designs closer than is customary in North America. Not something I'm certain I would want to do merely in the name of higher efficiency ( or bragging rights ).

The first time I heard of afterburner woodstoves with hot water flywheels was over 20 years ago from the work of Richard Hill, professor of engineering at University of Maine, Orono. He was adapting designs that were already being used industrially to garage size. I think a lot of us are trying to adapt european designs to American standards, whomever was the first to develop them. They are just ahead of us on the high efficiency domestic wood heating stuff. But whenever we try to translate other languages and cultures we make assumptions and it's those assumptions I'm questioning here.

Lord, I can get wordy over my 1st cup of coffee in the morning!

The first time I heard of afterburner woodstoves with hot water flywheels was over 20 years ago from the work of Richard Hill, professor of engineering at University of Maine, Orono. He was adapting designs that were already being used industrially to garage size. I think a lot of us are trying to adapt european designs to American standards, whomever was the first to develop them. They are just ahead of us on the high efficiency domestic wood heating stuff. But whenever we try to translate other languages and cultures we make assumptions and it's those assumptions I'm questioning here.

Lord, I can get wordy over my 1st cup of coffee in the morning!

Hansson

Feeling the Heat

I am getting my hole tank upp to 105 Celsius.

My system pressure is abut 0,7bar

Al system are pressurized here in Sweden so that temperatures are not unusual

Check out my friends system log.

The stratafcation is not good at this moment but this is because a flow meter.Dont now the English word:-(

http://www.afabinfo.com/baxilogg.asp

My system pressure is abut 0,7bar

Al system are pressurized here in Sweden so that temperatures are not unusual

Check out my friends system log.

The stratafcation is not good at this moment but this is because a flow meter.Dont now the English word:-(

http://www.afabinfo.com/baxilogg.asp

Attachments

Nofossil

Moderator Emeritus

Hansson said:I am getting my hole tank upp to 105 Celsius.

My system pressure is abut 0,7bar

Al system are pressurized here in Sweden so that temperatures are not unusual

Check out my friends system log.

The stratafcation is not good at this moment but this is because a flow meter.Dont now the English word:-(

http://www.afabinfo.com/baxilogg.asp

I'm thankful you're willing to post - your English is a whole lot better than my Swedish!

The high storage temperature is interesting to me, because it implies some loss of efficiency due to higher flue temperatures as well as higher standby losses. I've been looking at ways to use lower temperature stored water more effectively, and to get the coldest possible temperatures in the bottom of my stratified storage tank.

Thanks again for your post. It's nice to see what is being done in other places.

Willman

Minister of Fire

Hello again, Hansson and thank you. When I posted the original question here I couldn't find any pictures so I thought maybe I was dreaming.

Your system pressure (,7 bar is about 10 pounds/in.) is very close to our systems. Tarm starting pressure is 12 pounds/inch (just over ,8 bar). I think others are similar. I can see a safety issue if there was a break in the system and it lost pressure; not only hot water would escape but there would be a steam jet that might be very exciting in a large volume system. I think the boiler professionals on this forum probably have a word for that phenomenon. As your storage gets hotter does your boiler slow down to match the smaller temperature difference? Is it not harder to put the heat into storage as the temperature goes higher? As Nofossil says, it seems there is a loss of efficiency as storage temperatures go up. Maybe losing more heat to the surrounding room is not important if you want to heat that room anyway, but losing heat up the chimney is painful.

I see a dilemma here. The design swings between the convenience of having a longer time between boiler fires and some loss of energy efficiency to get that convenience. And I think that dilemma exists as soon as you go above room temperature. Looking at your link to your friend's site and Nofossil's site over here, I think smart people are measuring the things that must be measured. Maybe they can make a graph comparing heat lost up the chimney and storage temperatures. If the line is gradual then maybe the choice is just personal preference.

Please, make no apology for your English. We speak American here, not English. Spelling and grammar are not very important. I'm sorry I can't think of simpler ways to say what I want to say. All of your posts have been very interesting and good information.

Your system pressure (,7 bar is about 10 pounds/in.) is very close to our systems. Tarm starting pressure is 12 pounds/inch (just over ,8 bar). I think others are similar. I can see a safety issue if there was a break in the system and it lost pressure; not only hot water would escape but there would be a steam jet that might be very exciting in a large volume system. I think the boiler professionals on this forum probably have a word for that phenomenon. As your storage gets hotter does your boiler slow down to match the smaller temperature difference? Is it not harder to put the heat into storage as the temperature goes higher? As Nofossil says, it seems there is a loss of efficiency as storage temperatures go up. Maybe losing more heat to the surrounding room is not important if you want to heat that room anyway, but losing heat up the chimney is painful.

I see a dilemma here. The design swings between the convenience of having a longer time between boiler fires and some loss of energy efficiency to get that convenience. And I think that dilemma exists as soon as you go above room temperature. Looking at your link to your friend's site and Nofossil's site over here, I think smart people are measuring the things that must be measured. Maybe they can make a graph comparing heat lost up the chimney and storage temperatures. If the line is gradual then maybe the choice is just personal preference.

Please, make no apology for your English. We speak American here, not English. Spelling and grammar are not very important. I'm sorry I can't think of simpler ways to say what I want to say. All of your posts have been very interesting and good information.

chuck172

Minister of Fire

"Wow a Swedish nofossil "-that's funny

Hansson, take that as a compliment. Nofossil is a very smart and highly respected member of this forum.

Hansson, take that as a compliment. Nofossil is a very smart and highly respected member of this forum.

Hansson

Feeling the Heat

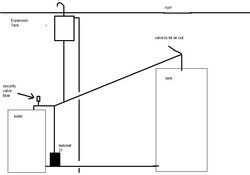

Hello.

I have an open system.If the boiler starts to boil the steam go out on the roof.

Se the simple system sketch i made.Very simple.Do not laugh...

The flu temperatures are not going to get higher.

If the boiler gets to hot the fan shuts off. No draft

Its a big difference when I just burn so the temperatures in the tanks come up to 80 Celsius.

In the summer I lose 2 days.In the winter when its -25 Celsius i have to put the tanks up to at least 90 one time per day.

Maybe we go for higher temperatures because we got smaller tanks?

When we not are using a expansions tank like i have you got to have a "syr valve" thats keeps the system temp below 90-94 Celsius.

If the system temp becomes higher it dumps hot water to the drain

Here is an other Swedish nofossil

http://web.telia.com/~u07102169/

this guy have good stratafcation.

/Hansson

I have an open system.If the boiler starts to boil the steam go out on the roof.

Se the simple system sketch i made.Very simple.Do not laugh...

The flu temperatures are not going to get higher.

If the boiler gets to hot the fan shuts off. No draft

Its a big difference when I just burn so the temperatures in the tanks come up to 80 Celsius.

In the summer I lose 2 days.In the winter when its -25 Celsius i have to put the tanks up to at least 90 one time per day.

Maybe we go for higher temperatures because we got smaller tanks?

When we not are using a expansions tank like i have you got to have a "syr valve" thats keeps the system temp below 90-94 Celsius.

If the system temp becomes higher it dumps hot water to the drain

Here is an other Swedish nofossil

http://web.telia.com/~u07102169/

this guy have good stratafcation.

/Hansson

Attachments

Nofossil

Moderator Emeritus

-25 C? That's T-shirt weather here ;-)

I think you answered my question. The higher temperature is a way to compensate for a smaller storage tank (ackumulatortankarna?)

The degree of stratification in the second link is impressive. Is that a sealed / pressurized system?

I'm also confused. I think you said that your system was pressurized to 0,7 bar in your previous post. We tend to think of 'closed' and 'pressurized' as the same, and opposite of 'open' or 'unpressurized'.

Has it since become unpressurized, or is the pressure maintained purely by the fact that the boiler is in the basement and the overflow is 5 meters or so above?

I think you answered my question. The higher temperature is a way to compensate for a smaller storage tank (ackumulatortankarna?)

The degree of stratification in the second link is impressive. Is that a sealed / pressurized system?

I'm also confused. I think you said that your system was pressurized to 0,7 bar in your previous post. We tend to think of 'closed' and 'pressurized' as the same, and opposite of 'open' or 'unpressurized'.

Has it since become unpressurized, or is the pressure maintained purely by the fact that the boiler is in the basement and the overflow is 5 meters or so above?

pybyr

Minister of Fire

very interesting- Thanks Hansson for posting this, as now we in the US that are still figuring out the implementation of these systems get to see how you Scandannavians who originated the technology go about using it.

and a follow-up question for you Hansson- is it typical for you folks in Scandanavia to use some sort of "boiler chemicals" to prevent oxidation corrosion in a system like yours that is open to the atmosphere at the top?

Nofossil- even though I'm not always swift at math, it does indeed seem as if the "pressure" in Hansson's system is about what the elevated tank would generate-

0,7 bar = (0.7 * 14.5 psi per bar) equals about 10psi And a column of water generates about 0.433 psi per vertical foot- so you can get to about 10 PSI at around the 23 foot level

and a follow-up question for you Hansson- is it typical for you folks in Scandanavia to use some sort of "boiler chemicals" to prevent oxidation corrosion in a system like yours that is open to the atmosphere at the top?

Nofossil- even though I'm not always swift at math, it does indeed seem as if the "pressure" in Hansson's system is about what the elevated tank would generate-

0,7 bar = (0.7 * 14.5 psi per bar) equals about 10psi And a column of water generates about 0.433 psi per vertical foot- so you can get to about 10 PSI at around the 23 foot level

heaterman

Minister of Fire

nofossil said:-25 C? That's T-shirt weather here ;-)

I think you answered my question. The higher temperature is a way to compensate for a smaller storage tank (ackumulatortankarna?)

The degree of stratification in the second link is impressive. Is that a sealed / pressurized system?

I'm also confused. I think you said that your system was pressurized to 0,7 bar in your previous post. We tend to think of 'closed' and 'pressurized' as the same, and opposite of 'open' or 'unpressurized'.

Has it since become unpressurized, or is the pressure maintained purely by the fact that the boiler is in the basement and the overflow is 5 meters or so above?

Exactly right NoFo. The standing "head" of water column is what effectively seals the system so pressure can be developed while still being open to the atmosphere as a relief valve. In addition, the higher storage temp allows the use of smaller storage vessels, heat exchangers, circs etc. Every component can be smaller because a lower volume of water must be moved to transfer a given # of BTU's.

pybyr

Minister of Fire

the last post above answers a lot of questions- but what do these "pressurized but open on top" systems do about oxygen in the water and the corrosive effect it'd have on the boiler and other iron or steel items? Are chemicals used to deal with this? Or in practice, does so little oxygen actually migrate from the "open" parts of the system on top to the lower parts like the boiler, tank and circulators that it doesn't matter? If the latter, would that remain true if the system were unused during warmer months (oxygen might then migrate down so that the whole system is in more of an equilibrium, since it is not being driven out of the system by heat in the bottom)?

Hansson

Feeling the Heat

Hello

Sorry for the delay,but its really nice weather here.No time for Internet .

I'm not sure if i should call my system pressurized system? An open pressurized system is maybe better?

nofossil the second link logg is an open pressurized system like mine.The hot water is transfered by 2 15meters copper pipes.

One in the bottom of the tank.This one preheats the in coming water.And one in the top of the tank.

whit this way of make hot water you get very god stratification.

The expansions tank is mad of stainless steal. The pipe that is going up to the expansions tank is made of steal.

My system is build in the 1960.When I was chancing the expansions tank for a bigger one i found no corrosion.

Some people are putting an oil in the top of the expansions tank.paraffin oil i think.

But i think this is over kill.

The expansions tank shold be 4-5% of the system

Sorry for the delay,but its really nice weather here.No time for Internet .

I'm not sure if i should call my system pressurized system? An open pressurized system is maybe better?

nofossil the second link logg is an open pressurized system like mine.The hot water is transfered by 2 15meters copper pipes.

One in the bottom of the tank.This one preheats the in coming water.And one in the top of the tank.

whit this way of make hot water you get very god stratification.

The expansions tank is mad of stainless steal. The pipe that is going up to the expansions tank is made of steal.

My system is build in the 1960.When I was chancing the expansions tank for a bigger one i found no corrosion.

Some people are putting an oil in the top of the expansions tank.paraffin oil i think.

But i think this is over kill.

The expansions tank shold be 4-5% of the system

Attachments

MaineMike100

Member

Probably showing my ignorance due to newbie status, but NoFossil could you elaborate on your statetment of higher standby losses with the higher storage temp? I do agree with the higher flue temp. reducing boiler efficiency. However, I was under the assumption that as long as the storage tank is enclosed within the building envelope, any heat loss through the insulation would simply serve to assist in heating the house, so it's not really a "loss". Getting ready to build my own system in a new house under construction right now. With any luck I'll be up and running by fall.

Nofossil

Moderator Emeritus

MaineMike100 said:Probably showing my ignorance due to newbie status, but NoFossil could you elaborate on your statetment of higher standby losses with the higher storage temp? I do agree with the higher flue temp. reducing boiler efficiency. However, I was under the assumption that as long as the storage tank is enclosed within the building envelope, any heat loss through the insulation would simply serve to assist in heating the house, so it's not really a "loss". Getting ready to build my own system in a new house under construction right now. With any luck I'll be up and running by fall.

Good point - two kinds of loss. If the storage tank is in an area where the heat does you no good (outdoors, attic) then it's truly lost. Otherwise, it's lost in terms of its ability to heat a specific desired load such as DHW, but it may still provide a benefit by heating a portion of the living space. Some folks deliberately minimize the insulation to provide direct heat from the storage to the area where the storage tanks are. I prefer to have more control, but that's my personal issue.

MaineMike100

Member

Thanks, wasn't trying to find fault with your statement, just wanted to make sure I wasn't overlooking something for my system. I am planning to have the storage tank in the basement which will be heated anyway as a recreation room, so any loss will just minimize what that zone needs to accomplish.

Hansson

Feeling the Heat

nofossil said:MaineMike100 said:Probably showing my ignorance due to newbie status, but NoFossil could you elaborate on your statetment of higher standby losses with the higher storage temp? I do agree with the higher flue temp. reducing boiler efficiency. However, I was under the assumption that as long as the storage tank is enclosed within the building envelope, any heat loss through the insulation would simply serve to assist in heating the house, so it's not really a "loss". Getting ready to build my own system in a new house under construction right now. With any luck I'll be up and running by fall.

Good point - two kinds of loss. If the storage tank is in an area where the heat does you no good (outdoors, attic) then it's truly lost. Otherwise, it's lost in terms of its ability to heat a specific desired load such as DHW, but it may still provide a benefit by heating a portion of the living space. Some folks deliberately minimize the insulation to provide direct heat from the storage to the area where the storage tanks are. I prefer to have more control, but that's my personal issue.

Whit bad insulation you get less good stratification in the tank when the the tanks walls cool the water.

Good insulation is very important.

Hansson

Feeling the Heat

Hello

I found another guy in Sweden that have a page that shows his boiler and tank temperatures.

http://www.elstyrteknik.se/pannrum/

I found another guy in Sweden that have a page that shows his boiler and tank temperatures.

http://www.elstyrteknik.se/pannrum/

Hansson, Thank you for posting the elstyrteknik site. It will be very interesting to watch. Do you know how big (KW) his boiler and storage tank are? I don't read swedish except when some words are similar to english. Is "kontor" the temperature inside?

Hansson

Feeling the Heat

Sorry I don't now how big the boiler and the tank are.

UTE= Outside temp

KONTOR = Office

I think the guy have the boiler in the office building of his company Elstyrteknik.

In 3-4 weeks I am getting my own 1wire system.

It`s a guy that are going to start sell systems.I think its going to be really cool.

it is a box that have internet connection.You can have it to send text messages to your cell phone.

And it can be connected to your electricity meter so you can see your electricity consumption.

UTE= Outside temp

KONTOR = Office

I think the guy have the boiler in the office building of his company Elstyrteknik.

In 3-4 weeks I am getting my own 1wire system.

It`s a guy that are going to start sell systems.I think its going to be really cool.

it is a box that have internet connection.You can have it to send text messages to your cell phone.

And it can be connected to your electricity meter so you can see your electricity consumption.

Hansson

Feeling the Heat

Hansson,

Thanks again for posting...

The German site is pretty cool.

I understand the collectors and pumps, (different controllers for different parts of the day?), I like the stratification strategy using the mixing valves (in a diverting configuration).

I am assuming that the squares with diagonals are heat exchangers - flat plate maybe? For the pool and storage tank and DHW.

Do you know what kind of mixing/diverting valves are used for the storage tank stratification?

Please keep the posts coming...

It seems that the US has a ways to go to catch up with European hydronics efficiency..

Thanks,

Steve

Thanks again for posting...

The German site is pretty cool.

I understand the collectors and pumps, (different controllers for different parts of the day?), I like the stratification strategy using the mixing valves (in a diverting configuration).

I am assuming that the squares with diagonals are heat exchangers - flat plate maybe? For the pool and storage tank and DHW.

Do you know what kind of mixing/diverting valves are used for the storage tank stratification?

Please keep the posts coming...

It seems that the US has a ways to go to catch up with European hydronics efficiency..

Thanks,

Steve

Hansson

Feeling the Heat

SteveJ said:Do you know what kind of mixing/diverting valves are used for the storage tank stratification?

Thanks,

Steve

Hello

I`dont now.

Maybe something like this ?

http://www.acaso.se/english/termovar_af.htm

http://www.acaso.se/english/index.html

Hansson

Feeling the Heat

Hansson said:Hello

I found another guy in Sweden that have a page that shows his boiler and tank temperatures.

http://www.elstyrteknik.se/pannrum/

Now i have my logg runing

http://web.telia.com/~u88408780/trn_alla_48.jpg

http://web.telia.com/~u88408780/lcd_acktank.jpg

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 879

- Replies

- 0

- Views

- 454

- Replies

- 3

- Views

- 508

- Replies

- 36

- Views

- 5K