Now here is a good kicker for you. That ash which is pictured was pretty much dead when cut! So it was low moisture to begin with.

Shrinkage

- Thread starter Backwoods Savage

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Battenkiller

Minister of Fire

Backwoods Savage said:Now here is a good kicker for you. That ash which is pictured was pretty much dead when cut! So it was low moisture to begin with.

All the more puzzling. The world is a mysterious place, and not all of it's secrets are easily revealed. I'm beginning to suspect that wood gnomes may be responsible. ;-)

bogydave

Minister of Fire

Battenkiller said:bogydave said:each of your splits shrinks about 3/4".

I bet every wood type has a different shrink ratio. I have birch & spruce.

Not to offend, but I sincerely doubt that. Since these threads are already crossing, I'll post the table of wood shrinkage I posted on the other thread. Your woods of choice are highlighted in green.

Great table

How about how to read it, like the yellow birch.

I says dimensional lumber, how does it correlate to rounds & splits?

Hiram Maxim

Minister of Fire

All I know is after 2 years my main pile has definitely shrunk a good 6" from top to bottom.

And I will say this.... its ah HELL of a lot dryer and lighter in weight than it was a year ago.

Almost going to be upset about burning some of it this Winter.....almost!

And I will say this.... its ah HELL of a lot dryer and lighter in weight than it was a year ago.

Almost going to be upset about burning some of it this Winter.....almost!

Battenkiller

Minister of Fire

bogydave said:Great table

How about how to red it, like the yellow birch.

I says dimensional lumber, how does it correlate to rounds & splits?

The table was actually designed for woodworkers, but there is really no difference between the amount any given piece of wood will shrink as it dries. The column for tangential shrinkage is the amount a slab cut piece of wood will shrink following the grain lines (across the widest part of a wedge-shaped split). For yellow birch, that would be 9.2%. The radial dimension would be how much a quarter cut piece of wood will shrink across the grain (from the bark side to the center). For YB, that would be 6.3%. The T/R column is for the ratio between the two. This is highly important to woodworkers since it predicts how much a given species will keep it's shape as it shrinks. YB has a T/R ratio of 1.3. That means it is dimensionally very stable (1.0 would mean no change in shape at all). Yellow birch is valued by some musical instrument makers partly because of this feature.

bogydave

Minister of Fire

Thanks

Now it makes sense.

A perfect 100" (8'4") stack (Green- YB) of splits, would shrink 6.3" if at 0% moisture content. (in a perfect world)

So 4" or 5" of shrinkage of a 100" stack fire wood splits 10 - 20% moisture, would be a good reference in the real world.

Did i get it right? Close?

I know they still come to SE Alaska & cut Sitka spruce for piano soundboards. High dollar, huge trees & heli-log them

Now it makes sense.

A perfect 100" (8'4") stack (Green- YB) of splits, would shrink 6.3" if at 0% moisture content. (in a perfect world)

So 4" or 5" of shrinkage of a 100" stack fire wood splits 10 - 20% moisture, would be a good reference in the real world.

Did i get it right? Close?

I know they still come to SE Alaska & cut Sitka spruce for piano soundboards. High dollar, huge trees & heli-log them

Slow1

Minister of Fire

Hmmm.. so since it is related, do when do you measure your wood then eh? i.e. if you know you burn 4 cords a year it would seem that given a 10% shrinkage in drying (easy number, seems the table has 8% for oak and ash but I'm lazy on math) then I should be stacknig 4.4 cords of green now to have my 4 cords ready in two years or I just might be disappointed in a couple seasons...

The other thing in that table that surprises me is just how much shrinkage there is with the grain - which if I'm reading it right means that splits will actually get shorter as well when they dry. I recall when I started cutting I asked here if splits would shrink in length and the general consensus was that they wouldn't in any appreciable amounts. Again if I'm reading the table right, oak can shrink 4% - that would take a 16" split down to 15.3" or a 20" split down to 19.2" - that would seem noticeable to me.

The other thing in that table that surprises me is just how much shrinkage there is with the grain - which if I'm reading it right means that splits will actually get shorter as well when they dry. I recall when I started cutting I asked here if splits would shrink in length and the general consensus was that they wouldn't in any appreciable amounts. Again if I'm reading the table right, oak can shrink 4% - that would take a 16" split down to 15.3" or a 20" split down to 19.2" - that would seem noticeable to me.

burntime

New Member

Slow1 said:Hmmm.. so since it is related, do when do you measure your wood then eh? i.e. if you know you burn 4 cords a year it would seem that given a 10% shrinkage in drying (easy number, seems the table has 8% for oak and ash but I'm lazy on math) then I should be stacknig 4.4 cords of green now to have my 4 cords ready in two years or I just might be disappointed in a couple seasons...

The other thing in that table that surprises me is just how much shrinkage there is with the grain - which if I'm reading it right means that splits will actually get shorter as well when they dry. I recall when I started cutting I asked here if splits would shrink in length and the general consensus was that they wouldn't in any appreciable amounts. Again if I'm reading the table right, oak can shrink 4% - that would take a 16" split down to 15.3" or a 20" split down to 19.2" - that would seem noticeable to me.

Your making my head hurt :lol: I think you are more then making up for the shrinkage by using properly seasoned woood that burns hotter and is not giving off its heat to burn off the excess moisture...

SolarAndWood

Minister of Fire

Battenkiller

Minister of Fire

bogydave said:Thanks

Now it makes sense.

A perfect 100" (8'4") stack (Green- YB) of splits, would shrink 6.3" if at 0% moisture content. (in a perfect world)

So 4" or 5" of shrinkage of a 100" stack fire wood splits 10 - 20% moisture, would be a good reference in the real world.

Did i get it right? Close?

I know they still come to SE Alaska & cut Sitka spruce for piano soundboards. High dollar, huge trees & heli-log them

You'll see a lot more shrinkage in the stack height than wood shrinkage alone would predict. As the wood dries in the beginning stages and drops a lot of moisture rapidly, there will certainly be some settling going on as well. Since the wood is not deliberately placed so that the grain all runs the same way, there will be differential shrinkage going on within any stack. That alone will exacerbate the problem. Differential shrinkage is what is really responsible for chairs getting rickety in the winter. A well made chair will have the wood oriented in a way that keeps this movement to a minimum.

I take especially good care to cross stack the end of my stacks so they won't fall over. Then I tap them in various places with a hand sledge to get them to settle so they can't move and feel real solid. After a week or so, I have to do the same thing again. A month later, they're all rickety again and I redo the tapping procedure. When I dry my wood in the basement during the heating season, this happens every couple of days. Burners who have trouble getting their stacks nice and tight should experiment with this technique. You'd be surprised how much even the most carefully stacked wood will settle after you do this, even when done right after first stacking.

My personal opinion? The wood both shrinks and settles over time, but I can't go proving this on other folks' stacks. ;-)

Check out this link:

http://www.salondeguitaredemontreal.ca/exposants_fiche_en.aspx?expId=313

Maurice is a friend of mine from Queen Charlotte. He does the same thing you're talking about, but for guitar wood instead of pianos. He only goes for the highest quality Sitka and Western red cedar. Some of the old-growth cedar he gets out of there has about 40-50 grain lines/inch. Look at the size of some of the the trees he's cutting (Maurice is about 6'4") and you can see they are close to 2000 years old. For the record, he is only on the wood recovery end of things, not felling any of these noble giants).

Battenkiller

Minister of Fire

Slow1 said:The other thing in that table that surprises me is just how much shrinkage there is with the grain - which if I'm reading it right means that splits will actually get shorter as well when they dry.

I knew somebody'd call me on that. :lol:

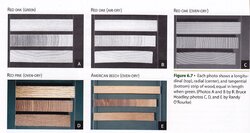

No, Slow, that's not what the table is measuring. You are thinking of shrinkage in the longitudinal dimension (that's the dimension guys worry about). I incorrectly used the term "along the grain" to try to describe the tangential dimension, but I should have known that might be confusing to non-woodworkers. Here's some photos of red oak, red pine and American beech as they shrink from the green state to 0% MC. The top board in each case is oriented in the longitudinal direction.

As you can see, there is almost no linear shrinkage (about 0.1% for most wood). If that wasn't the case, your stick-built exterior walls would be cracking drywall joints and breaking windows all over the place every season.

The second rows show views from the ends of the boards (or splits in our case), showing the orientation of the rings in a quartersawn board. You can see that there is shrinkage, but the board stays relatively the same shape.

The bottom rows show the ends of slab-cut boards (most common way building lumber is cut), and you can see how much more shrinkage there is, and how warped the boards get. You can also see that all of the boards cup in a predictable way - the opposite of the way the rings naturally curve. All wood will warp this way when cut in this manner.

All of the photos are of wood that has been oven-dried to 0% MC.

Attachments

Battenkiller

Minister of Fire

BLIMP said:maybe because the wood aint 100% dry, the residual moisture collapses the cells of the wood as it freezes & thaws?

Look into that for me, will ya? ;-)

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 909