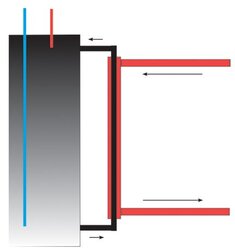

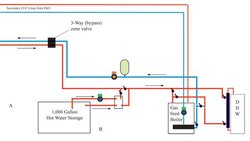

As part of my ongoing boiler upgrade, I decided to make a bigger sidearm heat exchanger for getting heat from the heating system into the water heater. This one uses a 1.5-inch shell with a 1" boiler water inlet and outlet. The tube (domestic hot water) going down the middle is 3/4-inch copper. When you pump 160+ degree water through the shell from top to bottom, it causes the domestic water in the 3/4-inch tube to convect by gravity, heating up a 50-gallon hot water heater surprisingly fast. We've found that as long as we keep the boiler going, we never run out of hot water.

I cobbled this together mostly from parts I had on-hand, which explains the coupling and series of reducers. If you were going to make one from scratch, you could get by with fewer, more specialized parts. I thought it was a good idea to pressure test the whole thing before installing it, since it took a fair amount of soldering and I was re-using most of the parts. Good thing, too, because it had two leaks that were relatively easy to fix as is, but would have been a nightmare once the thing is hooked up.

I cobbled this together mostly from parts I had on-hand, which explains the coupling and series of reducers. If you were going to make one from scratch, you could get by with fewer, more specialized parts. I thought it was a good idea to pressure test the whole thing before installing it, since it took a fair amount of soldering and I was re-using most of the parts. Good thing, too, because it had two leaks that were relatively easy to fix as is, but would have been a nightmare once the thing is hooked up.