Hi all,

Love the forum, seems like lots of helpful people.

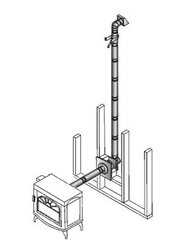

I recently bought an ESW 55-SHP25 and installed it in my house. We have a relatively large house (1st floor Approx 72' x 28'; 2nd floor ~38' x 24') with a very open floor plan in central MA. I usually keep the upstairs closed off. I have installed the stove relatively centrally in house and have a pretty even temperature throughout the house. I've installed a programmable thermostat and I like the performance.

My problem is the amount of ash and clinkers that are created overnight. I have adjusted the low burn feed and air rates (3-6-1) and have absolutely no problem when the stove is in low mode. As a matter of fact, I used about 3/4 of a bag over 24 hours when the stove is burning at low speed. However, when the outside temperature drops and the thermostat kicks on, I get a really large buildup of ash in the burn pot. I wake up in the morning and have to break up a 2"x 3" clinker every time. I have the high speed set at 8 feed and 9 room air. When I adjust it down to 5 feed rate, the clinkers are significantly smaller, but the stove is not able to keep up. I would assume that since the stove allows a 9 feed rate that it should burn reasonably well at this rate.

Is there any way to increase the burn air being fed into the pot at the higher feed rates?? Are there any other ways to reduce the clinkers at the higher feed rates??

I really like the stove, and have been using it continuously for almost a month now. We bought about 4 tons of pellets in advance, not knowing how much we would use, I expect at the rate we're going right now that we'll use 2.5 - 3 tons at most. Gotta love a $750 heating bill for the winter!

Thanks!

Love the forum, seems like lots of helpful people.

I recently bought an ESW 55-SHP25 and installed it in my house. We have a relatively large house (1st floor Approx 72' x 28'; 2nd floor ~38' x 24') with a very open floor plan in central MA. I usually keep the upstairs closed off. I have installed the stove relatively centrally in house and have a pretty even temperature throughout the house. I've installed a programmable thermostat and I like the performance.

My problem is the amount of ash and clinkers that are created overnight. I have adjusted the low burn feed and air rates (3-6-1) and have absolutely no problem when the stove is in low mode. As a matter of fact, I used about 3/4 of a bag over 24 hours when the stove is burning at low speed. However, when the outside temperature drops and the thermostat kicks on, I get a really large buildup of ash in the burn pot. I wake up in the morning and have to break up a 2"x 3" clinker every time. I have the high speed set at 8 feed and 9 room air. When I adjust it down to 5 feed rate, the clinkers are significantly smaller, but the stove is not able to keep up. I would assume that since the stove allows a 9 feed rate that it should burn reasonably well at this rate.

Is there any way to increase the burn air being fed into the pot at the higher feed rates?? Are there any other ways to reduce the clinkers at the higher feed rates??

I really like the stove, and have been using it continuously for almost a month now. We bought about 4 tons of pellets in advance, not knowing how much we would use, I expect at the rate we're going right now that we'll use 2.5 - 3 tons at most. Gotta love a $750 heating bill for the winter!

Thanks!

Too much information available!

Too much information available!