After a long regression to lurking, finishing renovations and wondering if I ever would hook up my BioMass I'm back.

Here is my situation

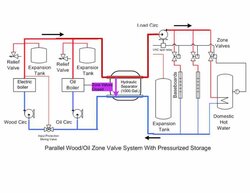

2 500 gal tanks stacked horizontally, welded up to be a hydraulic separator

1 BioMass 40

3 Zones Radiant

2 Zone Radiators

Electric hot water which I'd either like to hook up with a side arm or by immersing a copper coil in my tanks using a "manport" with two threaded fitting in it I had put in the tanks.

I've attached a lightly modified version of Simplest Pressurized and I am wondering If there is anything different I can/should do with the Circs or anything else because of the hydraulic separator.

(maybe I don't need a Load Circ?)

Also: I will be using an electric boiler as backup and I'm wondering if it makes sense to run it through the tanks or if I should should I bypass them somehow. The scenario I'm trying to avoid would be coming back after a weekend away with the tanks warmed by expensive electricity.

Thanks In Advance for your help

Augie

Here is my situation

2 500 gal tanks stacked horizontally, welded up to be a hydraulic separator

1 BioMass 40

3 Zones Radiant

2 Zone Radiators

Electric hot water which I'd either like to hook up with a side arm or by immersing a copper coil in my tanks using a "manport" with two threaded fitting in it I had put in the tanks.

I've attached a lightly modified version of Simplest Pressurized and I am wondering If there is anything different I can/should do with the Circs or anything else because of the hydraulic separator.

(maybe I don't need a Load Circ?)

Also: I will be using an electric boiler as backup and I'm wondering if it makes sense to run it through the tanks or if I should should I bypass them somehow. The scenario I'm trying to avoid would be coming back after a weekend away with the tanks warmed by expensive electricity.

Thanks In Advance for your help

Augie