Evening guys,

Here's some points in the manual for my Stockon 5.

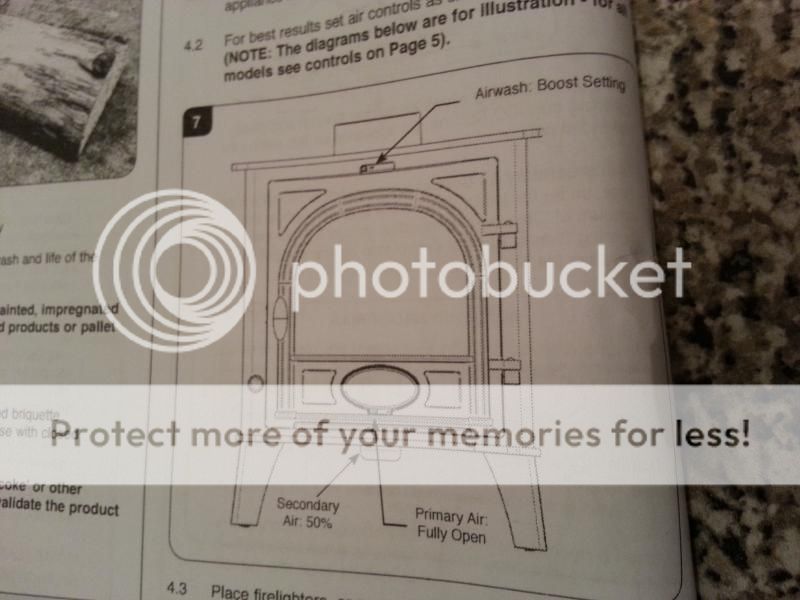

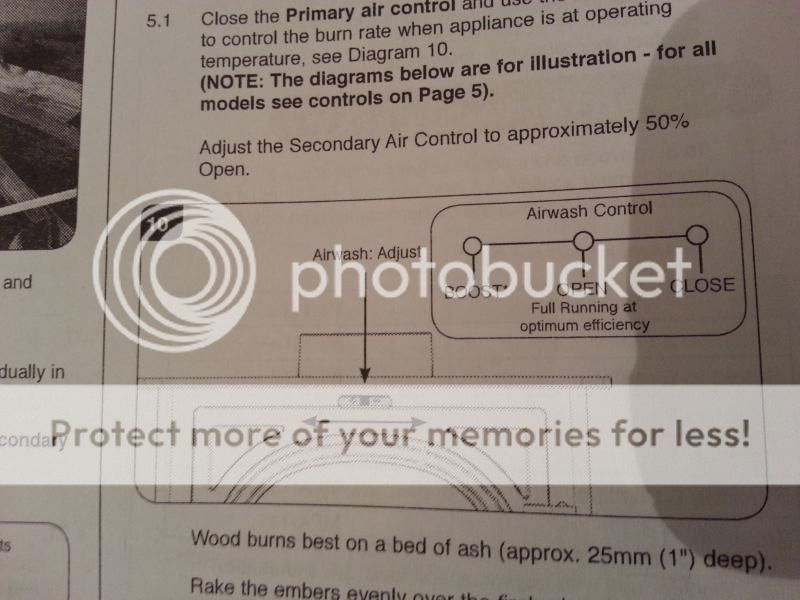

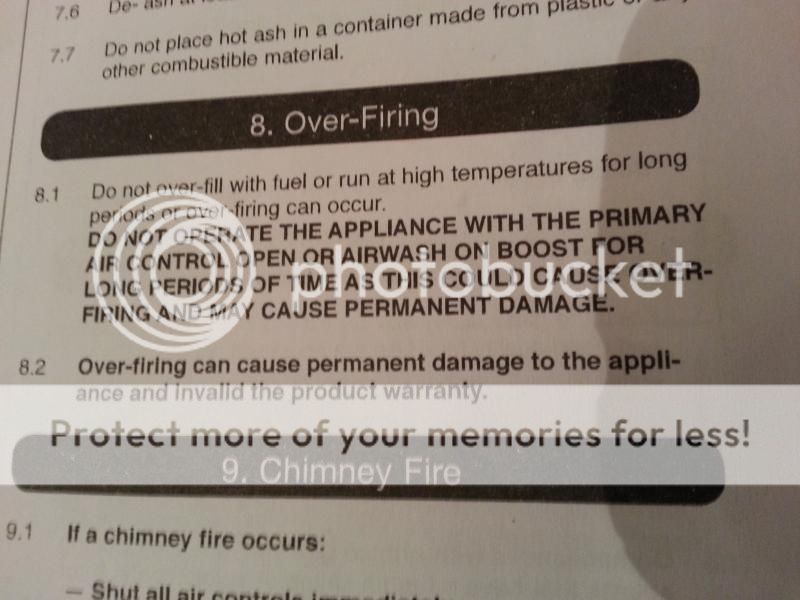

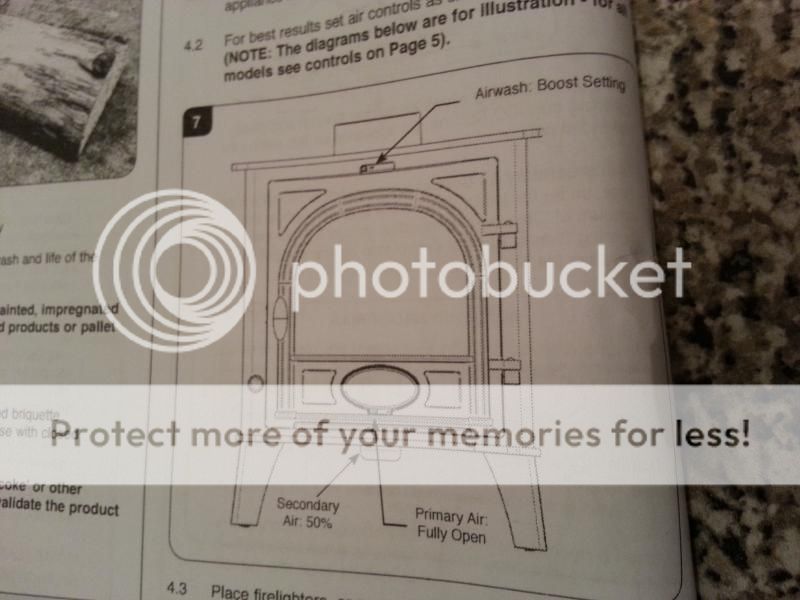

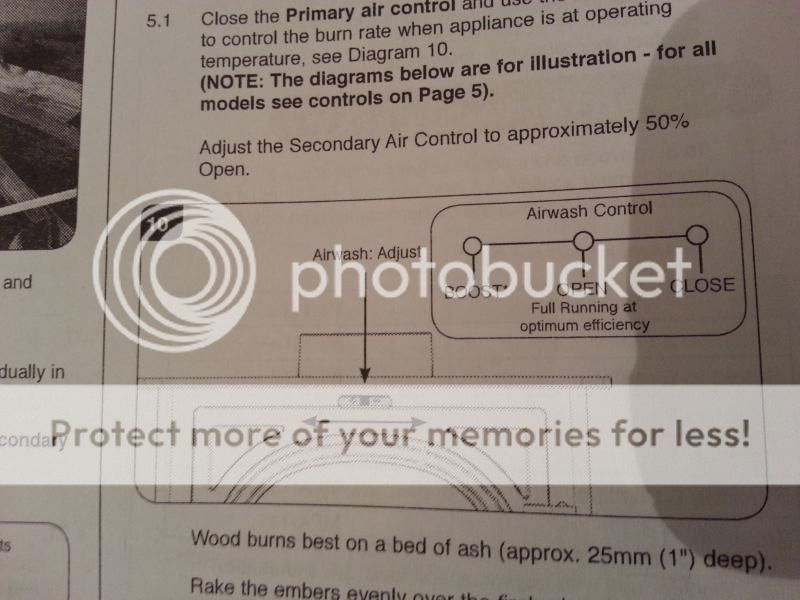

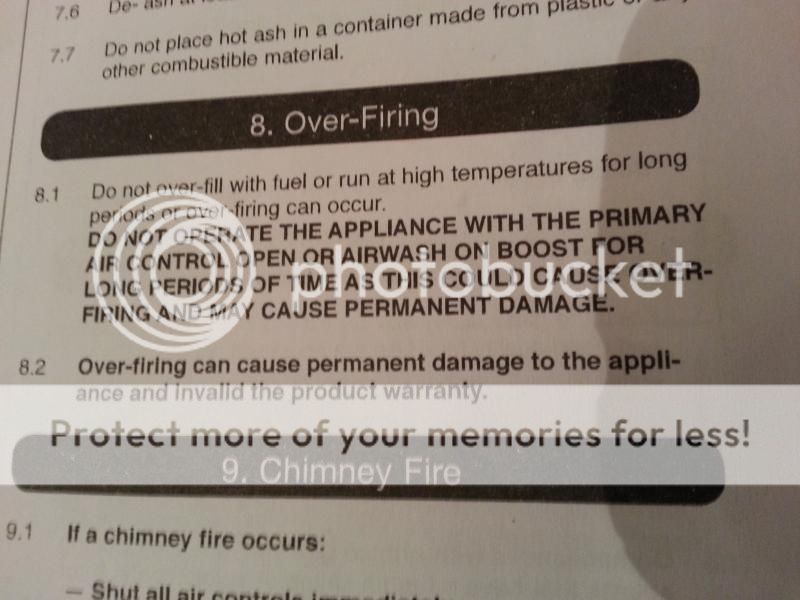

It talks a lot about not keeping the stove in boost setting on the airwash, and closing the primary down once the fire is going.

I've been leaving it in boost and also the primary open until its upto 350 *F. Then closing air down to slowly rise up to 400-450* F. Are all these warnings simply for people without a stove thermo to prevent overfiring? ie. as long as temps are in check no harm can be done from keeping the air controls open fully to get things going?

Secondary air - i've not really figured out, and left at 50%, doesn't appear to have much impact burning wood from what i've seen so far?

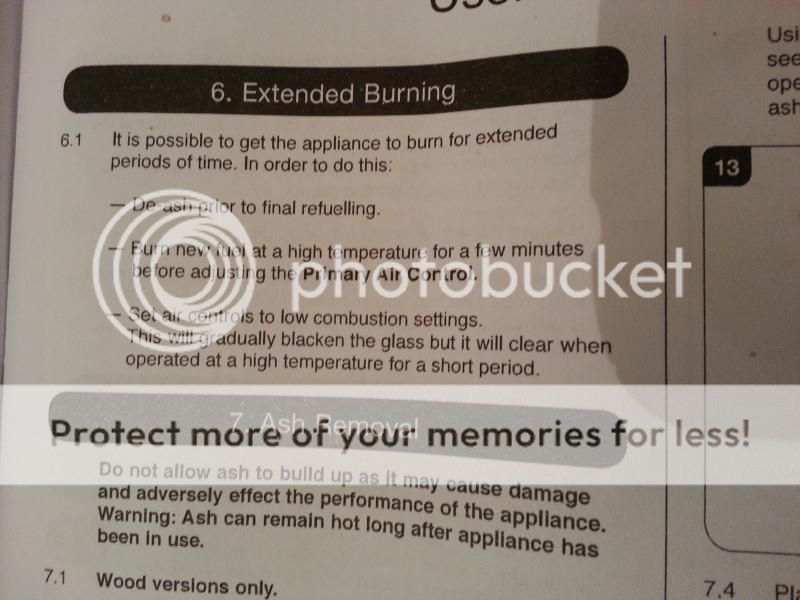

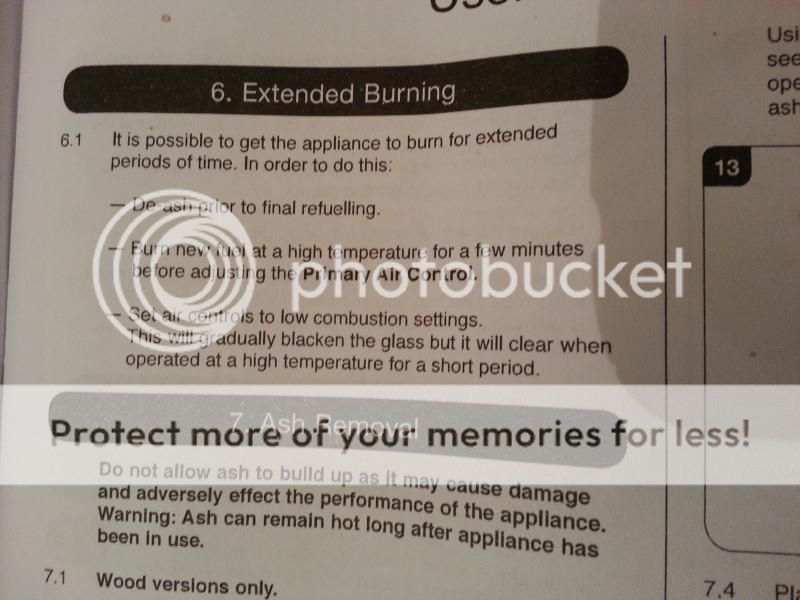

It also talks about burning a new load for a few minutes with primary open before adjusting it closed again, but i've found it better with primary open for 10-15 minutes to get a new load going properly?

Hottest i've had it so far is 500 on the flue thermo, I was concerned at this as its in the "too hot" area on the thermo and shut things down to bring it back to 450. Should I be concerned at 500 temps?

Just a sanity check really to make sure i'm running it ok and not causing damage

Here's some points in the manual for my Stockon 5.

It talks a lot about not keeping the stove in boost setting on the airwash, and closing the primary down once the fire is going.

I've been leaving it in boost and also the primary open until its upto 350 *F. Then closing air down to slowly rise up to 400-450* F. Are all these warnings simply for people without a stove thermo to prevent overfiring? ie. as long as temps are in check no harm can be done from keeping the air controls open fully to get things going?

Secondary air - i've not really figured out, and left at 50%, doesn't appear to have much impact burning wood from what i've seen so far?

It also talks about burning a new load for a few minutes with primary open before adjusting it closed again, but i've found it better with primary open for 10-15 minutes to get a new load going properly?

Hottest i've had it so far is 500 on the flue thermo, I was concerned at this as its in the "too hot" area on the thermo and shut things down to bring it back to 450. Should I be concerned at 500 temps?

Just a sanity check really to make sure i'm running it ok and not causing damage