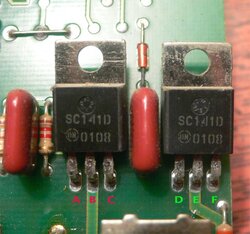

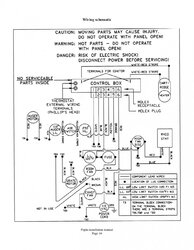

Hello, I'm running a St. Croix Pepin stove. When I turned on the power this morning, I saw a bright flash and the glass fuse blew inside (it does this maybe once a year, so it didn't seem unusual to me). I replaced, turned it back on, and now the auger motor will not stop turning. The feed light from the control panel comes on and off at the proper intervals but the auger turns regardless, and won't stop feeding pellets, no matter what I change the settings to.

Wires and connections all look good and snug.

Any ideas would be greatly appreciated, it is -16 today up North! Yikes

Thanks a ton

Wires and connections all look good and snug.

Any ideas would be greatly appreciated, it is -16 today up North! Yikes

Thanks a ton

Last edited:

I know the pain of cold, -14 F this AM now up to a whopping -22C but the sun is out.

I know the pain of cold, -14 F this AM now up to a whopping -22C but the sun is out.

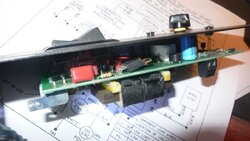

Maybe there's a trick, I can't see it. I've loosened the nut on the shaft of the heat adjustment control but I need the knob to come off to separate the board from the metal panel.

Maybe there's a trick, I can't see it. I've loosened the nut on the shaft of the heat adjustment control but I need the knob to come off to separate the board from the metal panel.