If stainless is very durable, gets hot fast, reflects heat, could burn off gases, doesn't rust, and is often used in secondary combustion, how come they don't line the inside of the wood stove with it?

Stainless Stove

- Thread starter Bill

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

babalu87

New Member

titan

Minister of Fire

Too bad they can't mak'em from magnesium-then little old ladies could swap out a stove by themselves! :cheese:

webbie

Seasoned Moderator

Stainless, depending on grade, is $1.50 to $4.00 or more (fancy grades).

Firebrick is very cheap - maybe 30 cents a brick.

But a bigger reason may be that stainless allows heat to transfer through it, while firebrick reflects inward and allows for higher temps and cleaner combustion..thereby allowing a stove to pass EPA standards easier.

It is possible that stainless could be used for afterburners in certain stove - in fact, I think it is used for baffles and some secondary tubes.

Firebrick is very cheap - maybe 30 cents a brick.

But a bigger reason may be that stainless allows heat to transfer through it, while firebrick reflects inward and allows for higher temps and cleaner combustion..thereby allowing a stove to pass EPA standards easier.

It is possible that stainless could be used for afterburners in certain stove - in fact, I think it is used for baffles and some secondary tubes.

TMonter

Minister of Fire

Stainless also has a very high coefficient of expansion and under high heat situations expands an awful lot making it very hard on welds.

Webmaster said:Stainless, depending on grade, is $1.50 to $4.00 or more (fancy grades).

Firebrick is very cheap - maybe 30 cents a brick.

But a bigger reason may be that stainless allows heat to transfer through it, while firebrick reflects inward and allows for higher temps and cleaner combustion..thereby allowing a stove to pass EPA standards easier.

It is possible that stainless could be used for afterburners in certain stove - in fact, I think it is used for baffles and some secondary tubes.

I would like to know were you can get bricks for 30 cents , around here they are $3 a piece .

webbie

Seasoned Moderator

I'm talking manufacturer prices - have not bought in a decade or so, but I used to get small quantities of split bricks for about 60 cents....not as an OEM, but buying them delivered by a masonry yard.

30 cents may be a little low, but I'd guess manufacturers are paying well less than a buck for splits (1/2 firebricks used in stoves).

I'm a bit behind the times as I have not been in the physical stove biz for about 8 years now (sold my shop in 1998).

The stainless prices I gave are also quantity prices for manufacturers....although the spread on metals is not usually as much - you can buy some stainless sheet on ebay for 2 bucks a pound plus shipping.

30 cents may be a little low, but I'd guess manufacturers are paying well less than a buck for splits (1/2 firebricks used in stoves).

I'm a bit behind the times as I have not been in the physical stove biz for about 8 years now (sold my shop in 1998).

The stainless prices I gave are also quantity prices for manufacturers....although the spread on metals is not usually as much - you can buy some stainless sheet on ebay for 2 bucks a pound plus shipping.

Webmaster said:I'm talking manufacturer prices - have not bought in a decade or so, but I used to get small quantities of split bricks for about 60 cents....not as an OEM, but buying them delivered by a masonry yard.

30 cents may be a little low, but I'd guess manufacturers are paying well less than a buck for splits (1/2 firebricks used in stoves).

I'm a bit behind the times as I have not been in the physical stove biz for about 8 years now (sold my shop in 1998).

The stainless prices I gave are also quantity prices for manufacturers....although the spread on metals is not usually as much - you can buy some stainless sheet on ebay for 2 bucks a pound plus shipping.

yes you're right , they do use stainless in secondary tubes , and i think a stainless stove is not practical .

Corie

Minister of Fire

Think about it too, the regular steel stoves seem to last forever as is makes me think it would be kinda hard to justify the overall cost of a completely stainless stove.

However, imagine how neat a non painted stainless stove would look after being fire a while. All rainbow colored and such. Oh well, guess I just like the way metal looks.

However, imagine how neat a non painted stainless stove would look after being fire a while. All rainbow colored and such. Oh well, guess I just like the way metal looks.

Corie said:Think about it too, the regular steel stoves seem to last forever as is makes me think it would be kinda hard to justify the overall cost of a completely stainless stove.

However, imagine how neat a non painted stainless stove would look after being fire a while. All rainbow colored and such. Oh well, guess I just like the way metal looks.

hard to keep clean dow.

stoveguy2esw

Minister of Fire

stainless would be impractical due to not only material cost, but also you would not be able to weld it with mig machines and wire, would likely have to be tig welded which is a more time intensive procedure, as well as one which requires a high degree of skill. there are other concerns as well already mentioned in this thread, but looking from a manufacturers standpoint the cost of materials and labor time per unit would make for an extremely costly unit. i do not think any manufacturer would attempt to field a line of this type for these reasons alone , much less so looking at the points raised about refractory rates and heat transparency

babalu87

New Member

stoveguy2esw said:stainless would be impractical due to not only material cost, but also you would not be able to weld it with mig machines and wire, would likely have to be tig welded which is a more time intensive procedure, as well as one which requires a high degree of skill. there are other concerns as well already mentioned in this thread, but looking from a manufacturers standpoint the cost of materials and labor time per unit would make for an extremely costly unit. i do not think any manufacturer would attempt to field a line of this type for these reasons alone , much less so looking at the points raised about refractory rates and heat transparency

I certainly hope anyone welding on a box that holds fire in someones home is highly skilled. Stainless is steel, plain and simple and if the people are trained properly the weld is the last thing anyone should worry about. Exhaust systems in boats go through 10 times the stress a wood stove would put on any weld/seam.

Highbeam

Minister of Fire

I keep thinking about the delorean. With the spread on wood stoves being very broad such as a 1200 dollar osburn to a 3100$ Hearthstone, there should be room for some alternative metals. Really though, the steel plate doesn't seem to wear out so whay bother?

Oh, and I can buy stainless steel welding rods for my arc welder, made of nickel or something. Nothing magical about stainless.

Oh, and I can buy stainless steel welding rods for my arc welder, made of nickel or something. Nothing magical about stainless.

webbie

Seasoned Moderator

Stainless is great to spot weld - and also electron beam weld. So we can have a spot welded stove!

Heck, it works fine for cars. If stainless was used, a stove might be able to be much thinner and lighter, which would make up for some of the price diff. Then you still have the paint problems.....cause the surface of stainless is generally smoother - chrome and nickel in it.

You would also burn your skin easier on it.

Heck, it works fine for cars. If stainless was used, a stove might be able to be much thinner and lighter, which would make up for some of the price diff. Then you still have the paint problems.....cause the surface of stainless is generally smoother - chrome and nickel in it.

You would also burn your skin easier on it.

babalu87

New Member

titan

Minister of Fire

--And a stainless Delorean woodstove would offer time travel when it reached 88*F -or was that mph? :coolgrin:

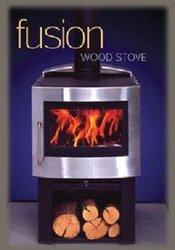

Aren't some of the new European stoves clad in stainless? At least that's what they look like. If there wasn't a fire burning in them you might think it's a circular refrigerator.

bacsales

New Member

I was thinking more of lining the with ss, wouldn't have to welded, could be stainless panels. You could put fire brick behind the SS. I just thought it would reflect the light from the fire better, burn off the gases faster, heat up faster, burn cleaner, burn hotter, but then again maybe it wouldn't.

I wasn't thinking of ss on the outside, but maybe you could chrome it. The thought of a chrome stove makes me laugh.

I wasn't thinking of ss on the outside, but maybe you could chrome it. The thought of a chrome stove makes me laugh.

titan

Minister of Fire

Hey maybe there's a developing market here....I could sell chromed-out stoves cw oversized doors and legs to the hip-hop crowd;investors line up here!IMPO too much shiny stuff is ugly,yet I'm a sucker for titanium or gun-metal grey.

BeGreen said:Aren't some of the new European stoves clad in stainless? At least that's what they look like. If there wasn't a fire burning in them you might think it's a circular refrigerator.

yes begreen, Napoleon oil stove have stainless steel mirrors to reflect the heat into the room.

tradergordo

Minister of Fire

Stainless steel is a relatively poor heat conductor. As a result, stainless steel cookware is generally made with a disk of copper or aluminium in or on the base to conduct the heat across the base. Go take a careful look at your stainless steel pots and pans.

This makes it great for secondary combustion chambers, burn tubes, and chimneys (in all cases where you want to "trap in" the high temps) but bad if you actually want to put heat into the room (i.e. for the stove itself).

This makes it great for secondary combustion chambers, burn tubes, and chimneys (in all cases where you want to "trap in" the high temps) but bad if you actually want to put heat into the room (i.e. for the stove itself).

Webmaster said:Stainless is great to spot weld - and also electron beam weld. So we can have a spot welded stove!

Heck, it works fine for cars. If stainless was used, a stove might be able to be much thinner and lighter, which would make up for some of the price diff. Then you still have the paint problems.....cause the surface of stainless is generally smoother - chrome and nickel in it.

You would also burn your skin easier on it.

no need to spot weld , stainless is weldable with a tig welder . and if you look at sum of these out side boilers, they are using stainless in the fire box. I just think that they would discolor and you wold not be able to maintain it appears. For instance, i have a stainless steal toaster oven and this thing is hard to keep clean after a wile it looks grows .

- Status

- Not open for further replies.

Similar threads

- Replies

- 13

- Views

- 799

- Replies

- 1

- Views

- 298

- Replies

- 2

- Views

- 916

- Replies

- 6

- Views

- 601