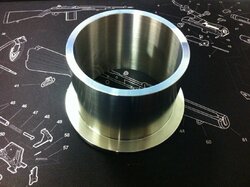

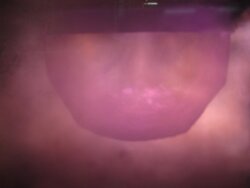

doing my sunday cleaning yesterday I decided that I was not happy with the nozzle erosion after 5-6 cords. its not bad, but i can see where it is going. made a steel liner and a plate to support it. 1/4" thick all around. nozzle liner is 3/4" smaller diameter than hole in ceramics. its 4140 as I did not have any stainless on hand. will have to see how long it lasts but I am interested now to see if it burns any different. fired with silver maple tonight. initial observations are 10*F increase in boiler temp and 20*C increase in flu temp. any idea why this could be? flame looks wicked, like BL wicked. also, there is a shot of my tunnel; barely starting to get thin at the bottom.

Attachments

-

IMG_1084.JPG148.8 KB · Views: 433

IMG_1084.JPG148.8 KB · Views: 433 -

IMG_1085.JPG121.8 KB · Views: 419

IMG_1085.JPG121.8 KB · Views: 419 -

IMG_1086.JPG136.2 KB · Views: 412

IMG_1086.JPG136.2 KB · Views: 412 -

IMG_1087.JPG263.1 KB · Views: 406

IMG_1087.JPG263.1 KB · Views: 406 -

IMG_1088.JPG195.9 KB · Views: 381

IMG_1088.JPG195.9 KB · Views: 381 -

IMG_1089.JPG148.7 KB · Views: 448

IMG_1089.JPG148.7 KB · Views: 448 -

IMG_1090.JPG109.1 KB · Views: 414

IMG_1090.JPG109.1 KB · Views: 414 -

IMG_1096.JPG151.2 KB · Views: 390

IMG_1096.JPG151.2 KB · Views: 390 -

IMG_1100.JPG90.5 KB · Views: 372

IMG_1100.JPG90.5 KB · Views: 372