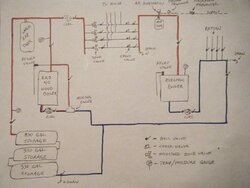

I am a bit confused about the flow of my system when both circulators are running. I question whether I will get flow into my storage tanks when I don't want it to go there. My system seems to be similar to NoFossil's "Simplest Pressurized Storage" but it looks like his would have the same issues. Will the amount of flow into the tanks be minimal because the load pump will be running? I have installed a valve (not shown) between the expansion tank and the storage tanks but am scratching my head as to whether this is neccessary or even how to control this valve. I would need it to open when the tank is charging (the load circ is off) as well as when heating from storage (the load circ is on and eko circ is off).

Also, My electric boiler has only one thermostat for all four zones. I have always had trouble keeping the zone that was furthest from the boiler warm. I plan on installing four thermostats for the eko in the four zones of the house to allow the furthest one to run longer. My electric boiler will run independent of the eko with its own thermostat. It will be set much lower than the eko and will kick on only when my storage is cold and the eko is not running. I know this is not the normal setup but does anyone see any issues with this?

Thanks for all the input.

Also, My electric boiler has only one thermostat for all four zones. I have always had trouble keeping the zone that was furthest from the boiler warm. I plan on installing four thermostats for the eko in the four zones of the house to allow the furthest one to run longer. My electric boiler will run independent of the eko with its own thermostat. It will be set much lower than the eko and will kick on only when my storage is cold and the eko is not running. I know this is not the normal setup but does anyone see any issues with this?

Thanks for all the input.