Hey guys, I need some help.

I want to hook up storage. Thinking about 1000 gallons. Only because it seems that is what most of you guys have.

I haven't done a heat loss calc so maybe that the first place to start to determine the size but lets say I go with a 1000.

I was thinking of getting one horizontal tank. Because I cant get it in the basement and my boiler is in the garage/boiler room, I figured it would be best to put it there.

originally I thought I would do two vertical 500 tanks but I am limited on space, so I thought I would dig a pit, much like a mechanics pit, in the center of the garage bay. I would form out the walls with concrete and then finish the top with removable steel grating.

I had a someone install my system and all though I do heat my house, you guys have said that it probably could have been a done little better.

Basically I have the Wood Gun in the garage/boiler room on the right side of the house.

I have 1" pex running for 63' with 4 elbows.

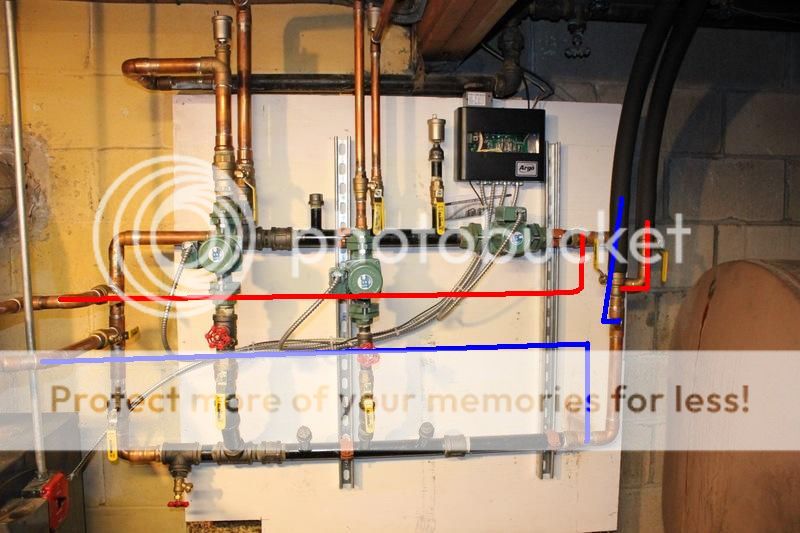

It then attaches to a loop of 1.25" copper hanging on the basement wall.

That loop is about 4' long by 2' high it has a 007 that pushes the water counterclockwise and then I have 2 zones which each have a 007 pulling the zone water back to the loop.

The Wood Gun has a 00R ifc 3 speed set on high pushing the supply water to the loop

My questions are (and I don't really even know what questions to ask):

1. My boiler would obviously be higher then the tank. Does that pose a problem?

2. How do I pipe it?

3. What else do I ask

I want to hook up storage. Thinking about 1000 gallons. Only because it seems that is what most of you guys have.

I haven't done a heat loss calc so maybe that the first place to start to determine the size but lets say I go with a 1000.

I was thinking of getting one horizontal tank. Because I cant get it in the basement and my boiler is in the garage/boiler room, I figured it would be best to put it there.

originally I thought I would do two vertical 500 tanks but I am limited on space, so I thought I would dig a pit, much like a mechanics pit, in the center of the garage bay. I would form out the walls with concrete and then finish the top with removable steel grating.

I had a someone install my system and all though I do heat my house, you guys have said that it probably could have been a done little better.

Basically I have the Wood Gun in the garage/boiler room on the right side of the house.

I have 1" pex running for 63' with 4 elbows.

It then attaches to a loop of 1.25" copper hanging on the basement wall.

That loop is about 4' long by 2' high it has a 007 that pushes the water counterclockwise and then I have 2 zones which each have a 007 pulling the zone water back to the loop.

The Wood Gun has a 00R ifc 3 speed set on high pushing the supply water to the loop

My questions are (and I don't really even know what questions to ask):

1. My boiler would obviously be higher then the tank. Does that pose a problem?

2. How do I pipe it?

3. What else do I ask