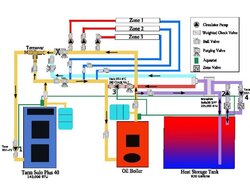

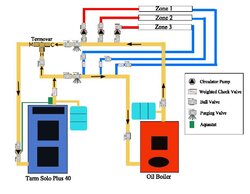

Here is my current thinking on how I can layout the piping for the open storage tank I am making. The first image is my current piping and the second is the planned piping.

Heating of tank - Pumps 1 & 4 come on together. Heated water travels through the oil boiler incase zones call for heat and then through the HX

Drawing from tank - Pumps 2 & 3 come on together. This circulates water from the oil boiler through the exchange. My DHW is always drawn from a coil in the oil boiler and all of the zones are fed from oil boiler.

A SPDT relay would be used to make sure all pumps do not run simultaneously (idea from nofossil)

I understand that my parallel piping is a variation from most, so I have tried to work things out as best I can based on what I currently have. There are two pumps on the tank side of the HX to maintain stratification.

The tank will be 930 gallons made of concrete in the basement corner with an EPDM liner and well insulated with polyiso.

Any feedback would be greatly appreciated.

Heating of tank - Pumps 1 & 4 come on together. Heated water travels through the oil boiler incase zones call for heat and then through the HX

Drawing from tank - Pumps 2 & 3 come on together. This circulates water from the oil boiler through the exchange. My DHW is always drawn from a coil in the oil boiler and all of the zones are fed from oil boiler.

A SPDT relay would be used to make sure all pumps do not run simultaneously (idea from nofossil)

I understand that my parallel piping is a variation from most, so I have tried to work things out as best I can based on what I currently have. There are two pumps on the tank side of the HX to maintain stratification.

The tank will be 930 gallons made of concrete in the basement corner with an EPDM liner and well insulated with polyiso.

Any feedback would be greatly appreciated.