Hello

It was hot last night and here is a list of what electric appliances were running:

1. Electric washer

2. Electric 240vac dryer with aluminum wiring

3. Three 110vac air conditioners 5x,10k and 12k BTUs

4. Pool filter pump 110v

5. Media Center - TV, Media Server, Surround Sound etc.

6. Desktop Computer

7. Kitchen Refrigerator

8. 2 or 3 Ceiling Fans

9. A few room lights

I would say maybe 60-70 Amps Total. The circuit box is a 23 yo Challenger made by GE and so is the 100 Amp main breaker and most of the other breakers. They do not seem like the best quality since I purchased the box and breakers at Somerville Lumber!

They are the same shape as square D.

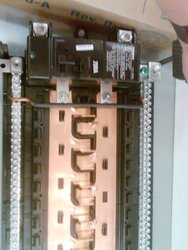

I took the front of the Circuit Panel off and I could feel the main breakers and they were HOT!

The main breaker plastic started melting. The wires from the meter socket were NOT warm.

Then other breakers started to trip, like the kitchen refrig and room light, then basement light!

What could be the cause?

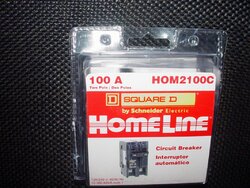

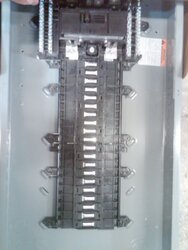

Tonight I removed the old 100 Amp main and replaced it with a new one.

See pics of old and new below!

Click on pic to enlarge

It was hot last night and here is a list of what electric appliances were running:

1. Electric washer

2. Electric 240vac dryer with aluminum wiring

3. Three 110vac air conditioners 5x,10k and 12k BTUs

4. Pool filter pump 110v

5. Media Center - TV, Media Server, Surround Sound etc.

6. Desktop Computer

7. Kitchen Refrigerator

8. 2 or 3 Ceiling Fans

9. A few room lights

I would say maybe 60-70 Amps Total. The circuit box is a 23 yo Challenger made by GE and so is the 100 Amp main breaker and most of the other breakers. They do not seem like the best quality since I purchased the box and breakers at Somerville Lumber!

They are the same shape as square D.

I took the front of the Circuit Panel off and I could feel the main breakers and they were HOT!

The main breaker plastic started melting. The wires from the meter socket were NOT warm.

Then other breakers started to trip, like the kitchen refrig and room light, then basement light!

What could be the cause?

Tonight I removed the old 100 Amp main and replaced it with a new one.

See pics of old and new below!

Click on pic to enlarge