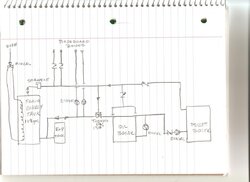

I find it too bad that after a zone or two drop out, the buffer tank is charged with the boiler at 100% power. I'd like to modulate the boiler down in these situations. One possible way, as Beagle Dad and nofossil have noted with a Froling wood boiler, is to control the return temperature. When the return temperature gets close to the boiler set point, my boiler modulates down to a minimum of 30%. It'd be nice to charge the buffer up nice and slow while keeping the boiler running when other zones kick on.

It would also be nice if the buffer could be 'emptied' while the boiler was still running, instead of it being a one way street-only charge the buffer, never discharge while the boiler is running.

I'm trying to come up with some ideas, but thought I'd throw this out there in case anybody has ideas. I will post further when I do.

It would also be nice if the buffer could be 'emptied' while the boiler was still running, instead of it being a one way street-only charge the buffer, never discharge while the boiler is running.

I'm trying to come up with some ideas, but thought I'd throw this out there in case anybody has ideas. I will post further when I do.